Abstract

Smart manufacturing with DELMIA brings next-level precision and adaptability to the construction sector. As infrastructure demands grow and timelines shrink, construction firms are turning to digital tools to plan, simulate, and optimize factory-like workflows for prefab elements, modular assemblies, and on-site execution.

In this article, we explore how DELMIA enables smarter layout planning, reduces material waste, and boosts operational efficiency, all within a unified, model-based environment on the 3DEXPERIENCE platform built for modern construction challenges.

Reimagining Construction Through Smart Manufacturing

Like most manufacturing industries, construction is undergoing a digital transformation. Traditional building processes — fragmented, reactive, and manual — no longer meet the demands of high-volume urban development or sustainable infrastructure projects. As more firms embrace off-site prefabrication, modular methods, and just-in-time material delivery, the line between manufacturing and construction begins to blur.

This is where smart manufacturing with DELMIA makes a profound impact. Originally designed to improve manufacturing workflows, DELMIA’s capabilities now extend to the construction industry, where similar challenges in layout, production planning, resource allocation, and execution arise.

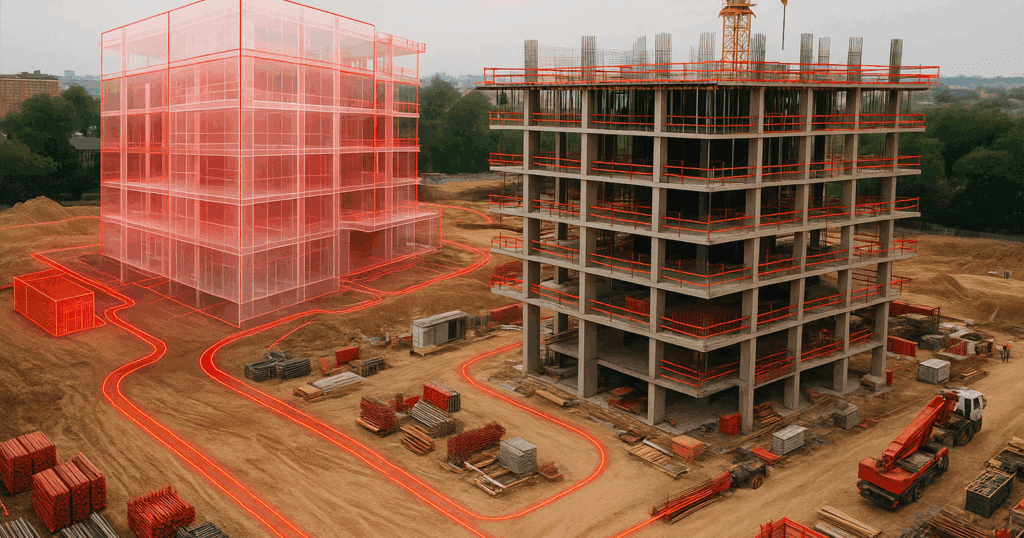

With DELMIA, construction teams can simulate, visualize, and optimize complex projects before ground is ever broken.

Virtual Factory Layouts for Prefab Construction

A significant number of modern construction projects now incorporate prefabricated elements. From concrete walls to fully outfitted bathroom pods, the demand for off-site production grows, but introduces new planning challenges.

DELMIA’s Solution

Smart manufacturing with DELMIA enables construction teams to design and test virtual layouts of their prefab production facilities. Using 3D modeling and digital twins, project managers can:

- Determine the most efficient equipment and material flow

- Minimize movement bottlenecks between assembly stations

- Simulate operator tasks and ensure ergonomic feasibility

- Optimize use of space and storage for large components

Rather than rely on spreadsheets and floor markings, teams can create a full virtual factory that supports lean manufacturing methods applied to construction. This level of simulation saves both time and money, all before any equipment is installed.

Reducing Waste with Digital Resource Planning

In traditional construction workflows, material waste is expected. Over-ordering, inaccurate cuts, and miscommunications between teams all contribute to inflated costs and environmental impacts.

Smart manufacturing with DELMIA addresses this problem at the source: through intelligent planning and resource simulation.

Material Flow Optimization

With DELMIA’s advanced planning capabilities, teams can digitally simulate the path of materials from delivery through fabrication to final installation. This includes:

- Identifying points of excess motion or delay

- Reducing overstock through just-in-time inventory strategies

- Planning cutting and joining operations with minimal offcuts

Instead of discovering waste after it happens, project teams can predict and prevent it through simulation-driven design.

Improving Workforce Efficiency

Construction firms face increasing pressure to deliver more with fewer skilled laborers. Workforce availability fluctuates, safety regulations increase, and project timelines shrink. In this context, optimizing human time and effort becomes a business-critical strategy.

Smart manufacturing with DELMIA helps by allowing construction planners to:

- Assign and simulate crew tasks in advance

- Balance workloads across shifts and departments

- Identify unsafe tasks before execution

- Provide training using realistic, immersive scenarios

By virtually validating workforce schedules and workflows, DELMIA ensures labor is used efficiently without compromising safety or quality.

Site Execution Management and Visibility

Once construction begins, managing execution across suppliers, subcontractors, and crews becomes a monumental coordination task. Delays, cost overruns, and avoidable rework often stem from poor communication and data silos.

Smart manufacturing with DELMIA solves this with integrated site execution tools that provide real-time visibility across the project lifecycle. Managers and stakeholders gain access to dashboards that show:

- Task progress and dependencies

- Material availability and consumption

- Equipment utilization

- Workforce task status and reassignments

Instead of relying on outdated daily reports or manual tracking, site leaders can make data-informed decisions in real time. When delays arise, alternate plans can be simulated and deployed within hours, not days!

Simulation for Logistics and Installation

Beyond the factory or jobsite, construction logistics represent a major variable in project success. Just-in-time delivery of oversized components, crane scheduling, and on-site staging all benefit from simulation.

DELMIA’s Logistics Capabilities

Smart manufacturing with DELMIA gives you full visualization of:

- Component transport and routing

- On-site crane and equipment operations

- Delivery sequencing and site storage planning

- Installation simulations, including clash detection and motion studies

This helps teams avoid costly surprises, like delayed deliveries or impossible installation angles, by validating each step digitally before it’s executed.

Supporting Sustainability and Compliance

Smart manufacturing with DELMIA isn’t just about speed and efficiency, it also supports sustainability goals. By reducing material waste, lowering energy consumption, and improving project accuracy, DELMIA contributes to:

- Reduced carbon emissions from rework and overproduction

- Smarter sourcing with digital supplier planning

- Easier documentation for green building certifications (e.g., LEED, BREEAM)

Moreover, its traceability tools provide construction teams with transparent audit trails for materials, processes, and labor essential for both regulatory compliance and ESG reporting.

Closing the Loop: From Design to Execution

One of DELMIA’s greatest strengths is its integration within the broader Dassault Systèmes 3DEXPERIENCE platform. Data created during design and engineering flows seamlessly into planning, production, and construction execution environments.

This continuity eliminates silos and manual handoffs that often lead to rework or misinterpretation. Through model-based systems engineering, teams can:

- Start with a 3D model of the building or prefab unit

- Simulate the entire construction process in a digital twin

- Push real-time updates and field data back into the design model

Smart manufacturing with DELMIA enables this end-to-end feedback loop, making every new project smarter than the last.

Conclusion: Building Smarter with DELMIA

Construction projects are growing in complexity, scale, and expectation, and traditional methods are struggling to keep up. Whether prefabricating building elements or coordinating complex site execution, forward-thinking firms are reaping the benefits of Smart Manufacturing.

From optimized layouts and reduced waste to better workforce utilization and digital logistics, DELMIA offers a powerful toolkit for construction leaders who want to plan better, build faster, and deliver more sustainably.

As construction evolves into a precision-driven, digitally connected process, tools like DELMIA are paving the way for smarter, safer, and more successful building, one project at a time.