Abstract

The engineering world is evolving rapidly. Design teams are under constant pressure to create lighter, stronger, and more sustainable products while cutting costs and speeding development. Traditional prototyping, once the industry standard, is no longer fast or efficient enough. By the time a physical prototype is tested, design changes are often expensive or impossible to implement.

This is where SIMULIA engineering simulation software makes a difference. By integrating simulation directly into the design process, it empowers designers to validate concepts earlier, improve collaboration, and unlock innovation at a faster pace.

This article explores SIMULIA’s capabilities, why it matters for modern design, and how companies across industries are using it to stay competitive.

The Shift from Analysis Bottlenecks to Integrated Simulation

In the past, design and simulation were entirely separate domains. Designers focused on geometry, while analysts were responsible for validating product performance. A typical workflow looked like this:

- A designer built a CAD model.

- That model was handed over to analysts.

- Analysts set up complex finite element models, ran simulations, and reported results.

- The designer made changes based on the feedback.

This cycle could take weeks, often delaying projects and limiting creativity. A designer might hesitate to try something unconventional, knowing that waiting for results would add time and cost.

SIMULIA engineering simulation software changes this by embedding performance validation into the design phase. Instead of sending work out for analysis, designers can run their own simulations directly within the CAD environment. This empowers them to explore more ideas, test alternatives, and identify problems long before a prototype is built.

Why SIMULIA Stands Apart

Many tools offer simulation, but SIMULIA has unique strengths that make it particularly valuable to designers:

Proven Technology: At its core, SIMULIA leverages Abaqus: one of the most trusted solvers in engineering. Abaqus is known for its accuracy in nonlinear mechanics, contact problems, and fatigue analysis.

Breadth of Physics: Designers can run structural, thermal, fluid, and electromagnetic simulations in a single environment. This multiphysics capability allows them to study complex, real-world interactions.

Scalability: A quick stress check can be run on a laptop, while a detailed crash simulation can scale to high-performance cloud computing. SIMULIA makes it easy to match resources to the complexity of the problem.

Designer-Friendly: Guided workflows, templates, and automated meshing lower the barrier to entry. Designers can run meaningful studies without advanced FEA expertise.

Collaboration at Scale: Integrated with the 3DEXPERIENCE platform, results are stored in a centralized environment. Everyone from designers to managers has access to the same up-to-date data.

Designer Empowerment Without Complexity

Traditionally, simulation software was intimidating. It required a steep learning curve and advanced mathematical knowledge. Designers were rarely expected to interact with these tools directly.

With SIMULIA engineering simulation software, that barrier is gone. Intuitive interfaces, streamlined setup, and guided analysis steps make it possible for non-specialists to perform accurate simulations. Designers can answer questions such as:

- Will this bracket deform under load?

- Does this electronics housing dissipate heat efficiently?

- Will vibration affect the performance of this assembly?

- Is this consumer product durable enough for everyday use?

By answering these questions themselves, designers can move forward with confidence, reducing the need for back-and-forth iterations. Analysts are still critical for highly complex studies, but much of the early validation can now happen at the design level.

Advanced Capabilities for Realistic Results

While accessible, SIMULIA does not sacrifice technical depth. It provides capabilities that ensure results are realistic and reliable.

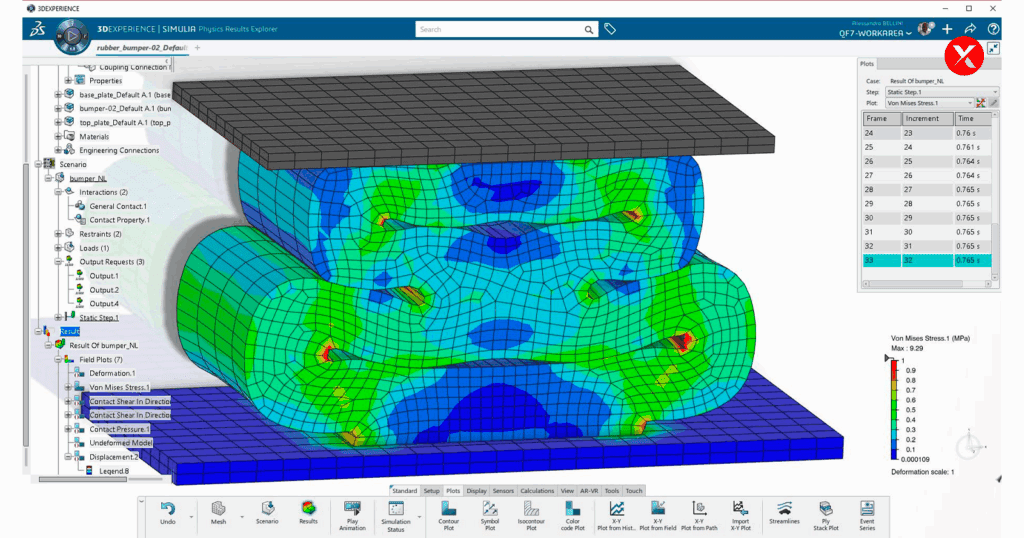

Nonlinear Analysis: Essential for modeling contact, large deformations, and materials like plastics or composites that do not behave linearly.

Durability and Fatigue: Predicts how long a part will last under repeated loading, helping reduce failures and warranty costs.

Crash and Impact Simulation: Particularly valuable in automotive, allowing engineers to test safety features without building full crash prototypes.

Computational Fluid Dynamics (CFD): Models airflow, turbulence, and thermal transfer — critical for aerodynamics, HVAC systems, or cooling electronics.

Electromagnetic Simulation: Useful for designing antennas, sensors, or consumer devices with wireless communication.

This balance of accessibility and power makes SIMULIA suitable for both day-to-day design validation and more advanced engineering studies.

Industry Applications: Bringing Concepts to Life

One of the reasons SIMULIA engineering simulation software is so widely adopted is its adaptability across industries.

Automotive

SIMULIA helps automotive manufacturers test crashworthiness, optimize lightweight structures, and improve aerodynamics. For instance, a design team can run simulations to see how a car’s hood deforms during an impact, ensuring passenger safety while reducing material use.

Aerospace

In aerospace, fatigue life is a critical concern. Engineers use SIMULIA to model how aircraft components behave under fluctuating loads. They can also simulate thermal stresses at high altitudes, ensuring compliance with safety regulations.

Consumer Goods

Consumer product designers use SIMULIA to test durability, ergonomics, and heat management. A smartphone designer, for example, might simulate how the device handles heat buildup during heavy use, ensuring reliability and comfort.

Industrial Equipment

Heavy machinery must withstand extreme loads and comply with strict safety standards. With SIMULIA, companies can test structural integrity virtually, avoiding costly physical failures.

Collaboration on the 3DEXPERIENCE Platform

Simulation is most valuable when its results are accessible to everyone involved in product development. With SIMULIA on the 3DEXPERIENCE platform, simulation results are stored in a shared, cloud-based environment.

- Designers can validate models and share findings quickly.

- Analysts can refine simulations without rebuilding geometry.

- Managers gain access to clear, visual reports for decision-making.

This shared “single source of truth” eliminates silos and miscommunication. Teams spread across multiple locations can collaborate seamlessly, reviewing the same data in real time.

A typical workflow might look like this: a designer validates a bracket for stress, uploads the results, and tags an analyst. The analyst reviews the study, runs a more advanced fatigue analysis, and adds their results to the same project. A manager then reviews both reports and makes an informed decision about whether the design is production-ready.

Why SIMULIA Matters for Modern Engineering

Markets are more competitive than ever. Customers expect high performance, safety, and sustainability, while companies are under pressure to reduce costs and accelerate delivery. Physical prototyping alone cannot meet these demands. By bringing simulation into design, SIMULIA engineering simulation software delivers:

Faster Time-to-Market: Validation occurs during design, not after.

Reduced Costs: Fewer physical prototypes and less late-stage rework.

Higher Quality: Issues are identified and resolved before production.

Innovation at Scale: Designers can experiment freely, knowing they can test new ideas virtually.

This combination of speed, confidence, and creativity gives companies a decisive competitive edge.

Conclusion

Engineering is no longer about waiting for validation. With SIMULIA engineering simulation software, designers can drive innovation by testing, refining, and validating ideas directly within their workflow. Industries from automotive to consumer goods are using SIMULIA to cut costs, shorten timelines, and deliver better products.

By bridging the gap between creativity and certainty, it helps organizations stay ahead in a world that rewards agility and technical excellence.