Introduction: When Tools Multiply, Consistency Breaks

Engineering teams rarely struggle because of a lack of tools. More often, they struggle because those tools do not work together.

As teams grow, collaborate across disciplines, or support multiple products, workflows fragment. Files move between systems, revisions drift out of sync, and engineers spend increasing amounts of time validating data rather than designing. Data continuity and workflow consistency become difficult to maintain, even when everyone is doing their job correctly.

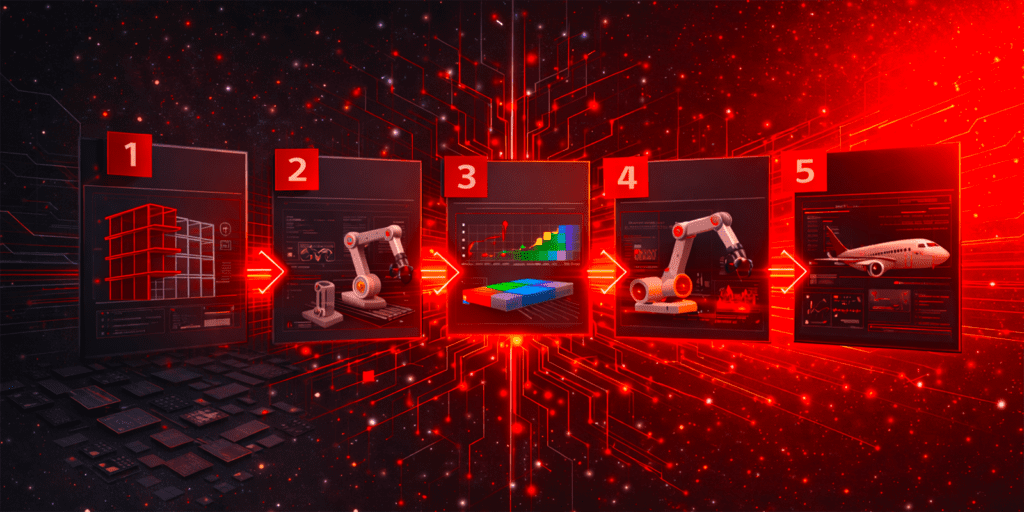

A digital engineering platform addresses this problem by shifting how engineering work is organized. Instead of relying on disconnected tools and handoffs, teams operate within a shared environment where data, workflows, and collaboration follow consistent rules.

This article explains how engineers can maintain data continuity and workflow consistency across teams by working within a single digital engineering platform, with a focus on the 3DEXPERIENCE platform.

Why Data Continuity and Workflow Consistency Matter to Engineers

For practicing engineers, data continuity is not an abstract concept. It shows up in daily frustrations.

Common symptoms include uncertainty about which version of a model is current, time spent reconciling changes made by other teams, manual tracking of approvals and review status, and broken references when designs move between tools or teams.

Workflow inconsistency compounds these issues. When different teams follow different processes, engineers cannot predict what will happen next or where responsibility lies.

Over time, these inconsistencies erode trust in the system. Engineers compensate by keeping local copies, creating parallel tracking methods, or delaying collaboration. Productivity drops not because of technical limitations, but because the environment does not support consistent work.

Understanding the Role of a Digital Engineering Platform

A digital engineering platform is not simply a collection of integrated tools. Its value comes from providing a shared structure for how engineering data and workflows behave.

At its core, the platform centralizes product data, standardizes lifecycle states and workflows, maintains relationships between data elements, and enables collaboration without duplicating information.

Instead of asking engineers to adapt to multiple systems, the platform adapts to the engineering process itself.

The 3DEXPERIENCE platform is designed around this concept. It connects design, validation, and collaboration within a single environment, allowing engineers to work with confidence that their data remains consistent as it moves across teams.

Data Continuity Starts with a Shared Data Backbone

Maintaining data continuity requires more than storing files in one location. It requires preserving context.

Moving Beyond File-Centric Work

In file-based environments, continuity depends on discipline. Engineers must remember where to save files, how to name them, and when to notify others of changes.

A digital engineering platform shifts this responsibility to the system. Data is managed as part of a connected structure rather than as isolated files.

This means relationships between parts and assemblies are preserved, metadata remains attached to the design, and revision history is visible and traceable. Engineers no longer need to reconstruct context manually.

Workflow Consistency Through Defined Processes

Workflow consistency does not mean rigid processes. It means predictable ones.

On the platform, workflows define how data moves through stages such as design, review, and release. These workflows are shared across teams, so engineers understand what actions are required and what status a design holds at any point.

With the 3DEXPERIENCE platform, lifecycle states are clearly defined, approval steps are visible, and changes propagate automatically. This consistency reduces ambiguity and prevents work from stalling due to unclear ownership or status.

Supporting Cross-Functional Collaboration Without Friction

Modern engineering work spans disciplines. Mechanical, electrical, simulation, and manufacturing teams all interact with the same product data.

In disconnected environments, collaboration introduces risk. Data is copied, translated, or simplified, increasing the chance of errors.

A digital engineering platform supports collaboration by allowing teams to work from a shared data source while interacting through role-appropriate views. Engineers can see how their work affects others, access related data without duplicating it, and collaborate without losing control of revisions.

Maintaining Engineer Autonomy Within a Shared System

One concern engineers often have is that platforms reduce flexibility. In practice, the opposite is true when platforms are implemented correctly.

A shared digital engineering platform handles data governance centrally and reduces administrative overhead. Engineers spend less time managing files and more time solving problems. Consistency is achieved through system design rather than enforcement.

Practical Questions Engineers Can Ask Today

Even within existing environments, engineers can benefit from platform-based thinking.

Key questions include where design data officially lives, how readiness for review or release is communicated, whether changes can be traced without manual tracking, and whether workflows help or hinder daily work.

The answers reveal whether continuity and consistency are system-supported or dependent on individual habits.

Reducing Friction

While a digital engineering platform provides the structure needed to maintain data continuity and workflow consistency, not all environments labeled as integrated offer the same foundation. Many engineering teams operate with connected tools that move data between systems but do not preserve context or enforce consistent behavior. Understanding this distinction is critical for engineers trying to reduce daily friction.

Conclusion: Consistency as an Enabler, Not a Constraint

Data continuity and workflow consistency are not about control. They are about confidence.

When engineers trust their data and understand how work flows across teams, collaboration becomes easier and errors become less frequent. A digital engineering platform provides the structure needed to support this confidence without adding unnecessary complexity.

By working within a shared platform such as the 3DEXPERIENCE platform, engineers can maintain continuity, reduce friction, and focus on what they do best: designing reliable, high-quality products.