Abstract

As modern vehicles grow increasingly sophisticated, automotive design teams must manage massive assemblies containing tens of thousands of interconnected components. Balancing aesthetic innovation with mechanical functionality—and doing so on aggressive development timelines—requires a new level of precision and efficiency.

At the center of this engineering revolution is CATIA for automotive design, a digital platform that empowers manufacturers to manage even the most complex assemblies with confidence. With advanced modeling, version control, simulation, and real-time collaboration tools, CATIA streamlines the development of next-generation vehicles, ensuring quality and performance at every stage.

This article explores how CATIA for automotive design helps automakers master complexity and deliver groundbreaking innovations faster and more efficiently.

The Growing Complexity of Automotive Engineering

Today’s vehicles are marvels of engineering integration. Electric drivetrains, lightweight materials, embedded sensors, and modular interiors are just a few of the innovations reshaping how cars are built. Each new technology adds more parts, more interfaces, and more systems that must work seamlessly together across diverse vehicle platforms.

Managing this explosion of complexity is one of the automotive industry’s biggest challenges. Development cycles are shrinking, while safety, performance, and environmental standards continue to rise. Without powerful digital tools, keeping track of how thousands of parts interact—and ensuring they fit together flawlessly—would be nearly impossible.

This is where CATIA for automotive design delivers critical value, transforming the way engineering teams visualize, validate, and manage their designs.

How CATIA Manages Complex Assemblies

CATIA for automotive design offers a comprehensive suite of capabilities purpose-built to handle the massive scale and intricacy of modern vehicle development. Whether designing a complete chassis or fine-tuning the fit between dashboard components, CATIA provides the flexibility and control required to manage complexity without sacrificing speed.

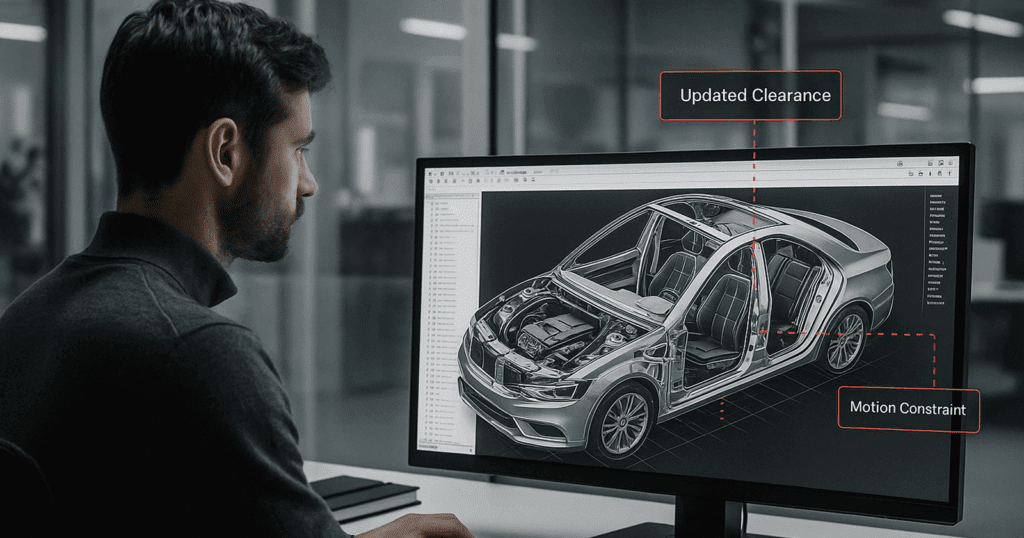

Top-Down Assembly Design

Rather than designing each part in isolation, CATIA for automotive design enables a top-down approach, where relationships between components are defined early and updated dynamically. Engineers can establish key parameters—such as clearances, alignments, and motion limits—that automatically propagate across the assembly as changes occur.

This ensures that as individual components evolve, the overall vehicle structure remains coherent, collision-free, and production-ready.

Lightweight Representations for Large Models

Full vehicle assemblies can contain millions of geometric elements. To maintain system responsiveness, CATIA allows engineers to work with lightweight versions of assemblies, loading only the necessary details while maintaining full associativity.

This feature enhances performance without sacrificing the ability to analyze critical interfaces, conduct validation studies, or ensure proper fit and function.

Concurrent Design Across Domains

Automotive design doesn’t happen in silos. Mechanical, electrical, electronic, and software teams all contribute to vehicle architecture. CATIA for automotive design allows different disciplines to work concurrently on the same master digital model, identifying conflicts early and reducing costly late-stage redesigns.

Through concurrent design, teams can make faster, smarter decisions with full confidence in data consistency.

Change Management and Configuration Control

In an environment where even minor design changes can cascade across multiple vehicle programs, traceability is essential. CATIA’s robust change management tools allow teams to track revisions, manage configurations, and ensure all stakeholders are working from the correct version of the design at all times.

This control over change enhances product quality and reduces costly rework caused by version mismatches.

Enabling Simulation and Validation Early in the Process

Complex assemblies are more than just geometric puzzles—they represent real-world behavior under diverse conditions. With CATIA’s integrated simulation capabilities, engineers can validate designs early in the development cycle, assessing factors like:

- Structural integrity under dynamic loads

- Thermal expansion impacts across materials

- Assembly feasibility and serviceability

- Tolerance analysis and variation simulation

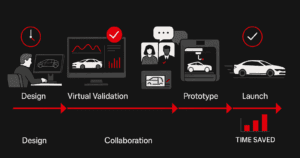

By enabling virtual testing long before physical prototypes are built, CATIA for automotive design dramatically shortens development timelines and improves first-pass success rates.

This proactive validation approach also enhances product quality, enabling teams to optimize interfaces, material choices, and component interactions before they reach production.

Supporting Modular and Platform-Based Engineering

To maximize flexibility and reduce costs, many automakers are adopting modular vehicle architectures—common platforms that support multiple models and variants.

CATIA for automotive design excels at enabling this modularity by supporting parametric design, shared subassemblies, and variant management strategies. Designers can create common modules for chassis, powertrains, or interiors and propagate updates across programs seamlessly.

By managing both commonality and customization at scale, CATIA empowers manufacturers to increase engineering efficiency while offering greater product diversity.

Reducing Development Costs and Time-to-Market

In today’s hypercompetitive automotive landscape, speed to market is essential. Traditional development approaches—reliant on sequential design and extensive physical prototyping—are simply too slow and expensive.

By fully digitizing the design, collaboration, and validation workflows, CATIA for automotive design enables teams to:

- Minimize the number of required prototypes

- Resolve design issues early and collaboratively

- Synchronize global teams through shared platforms

- Accelerate decision-making through real-time model visibility

This transformation in product development translates directly into cost savings, improved quality, and faster launch cycles.

Driving Innovation with Confidence

Modern automotive innovation spans lightweight structures, autonomous systems, electrification, and connected vehicle technologies. Each innovation demands precision engineering across multiple domains.

CATIA for automotive design provides the integrated environment required to master complexity and manage multidisciplinary programs. Engineers can push the boundaries of creativity without sacrificing control or manufacturability, resulting in vehicles that are smarter, safer, and more sustainable.

By embedding complexity management into the DNA of development, CATIA helps automakers bring breakthrough ideas to life faster and more reliably.

Conclusion: Master Complexity, Drive Innovation

As the automotive industry moves into an era of electrification, automation, and connected ecosystems, mastering complexity isn’t optional—it’s a necessity.

CATIA for automotive design delivers the tools engineers need to streamline assembly development, ensure seamless integration across systems, validate designs earlier, and foster smarter collaboration. With these capabilities, manufacturers can tackle the challenges of modern vehicle design and emerge as leaders in innovation, safety, and sustainability.

To discover how your teams can maximize the full potential of CATIA for automotive design, contact Mecanica today for expert insights and implementation support.