Introduction

The journey to create innovative designs is fraught with challenges related to changing industry regulations and sustainability, especially in surface modeling. This blog post explores the hurdles OEMs face and how our online CAD software CATIA, especially through the new application ICEM Design Experience (IDX), offers solutions to help surface modelers design better products.

Navigating Surface Modeling Challenges

In automotive and industrial design, achieving flawless surface finishes is akin to a painter perfecting the strokes on a masterpiece. However, OEMs encounter significant challenges and changes in the industry. Therefore, they need to ensure consistency and precision in surface modeling.

- Balancing Design and Technical Requirements: Designers, and more especially class-A modelers, must integrate various factors such as tooling directions, draft angles, curvature analyses and surface highlights while respecting the initial design intent. This delicate balance is crucial for maintaining product quality and brand identity.

- Evolving Surface Refinement Techniques: As surface refinement technologies continue to evolve, OEMs must streamline their processes to enhance productivity without sacrificing their exacting quality requirements. This involves adopting innovative tools and techniques swiftly to stay competitive.

- Sustainability Integration: Incorporating sustainable design from the inception is no longer optional. Many new startups understand that and are now putting pressure on traditional OEMs, who must consider ecological regulations, product longevity, sustainable energies and recycled materials early in their design process to be up to date.

“OEMs need to optimize their workflows to improve productivity while maintaining high-quality standards for their customers.” -Julien LACHICHI, CATIA Design Industry Process Expert

Advancing with CAD Modeling Techniques

To conquer these challenges, OEMs are turning to fresh and advanced CAD modeling techniques, which are transforming the design landscape

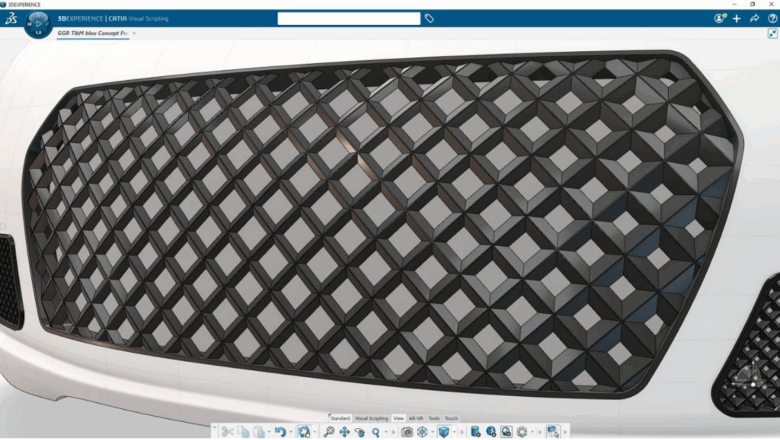

- Sub-D, Bezier, and NURBS Integration: These modeling techniques allow designers to explore innovative shapes and styles, meeting consumer demands for aesthetically pleasing and functional products.

- Additive Manufacturing: The synergy between CAD modeling and additive manufacturing enables the creation of unexpected, complex patterns and previously impossible designs, opening new avenues for creativity and innovation.

ICEM Design Experience: Enhancing Class-A Design Processes

ICEM Surf, the leading surface modeling software that has defined the industry standard for class-A for over 30 years, is like a master craftsman’s toolset for modelers. ICEM Design Experience, the new CATIA tool dedicated to CAS and class-A surface modeling, enhances the design process with precision and flexibility.

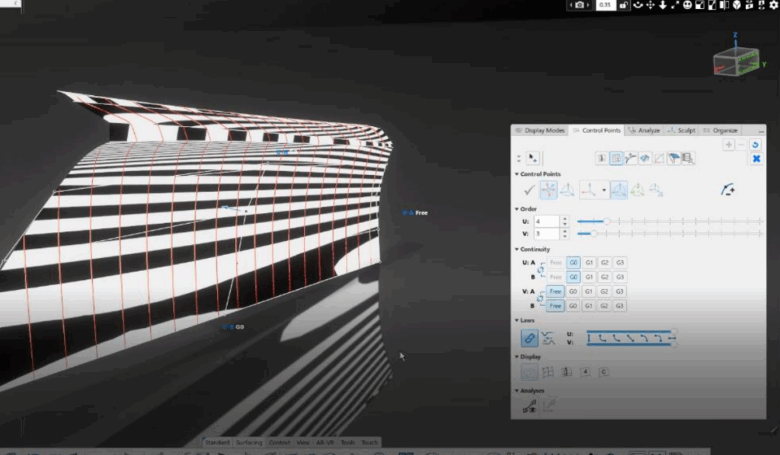

- Parametric Associativity: This feature allows for seamless updates and modifications. When changes are made to the parent curves, dependent elements like blend curves automatically adjust, ensuring a smooth workflow.

- Organizational Structure: Models are broken down into logical zones, allowing designers to focus on specific areas without touching the entire model. This possibility of having complete control over what parts can be updated enhances productivity, flexibility and precision.

- Integrated Visualizations: Built-in shaders and 3D visualization capabilities provide a clear perception of surface shapes and real-time feedback, helping designers quickly identify and rectify imperfections.

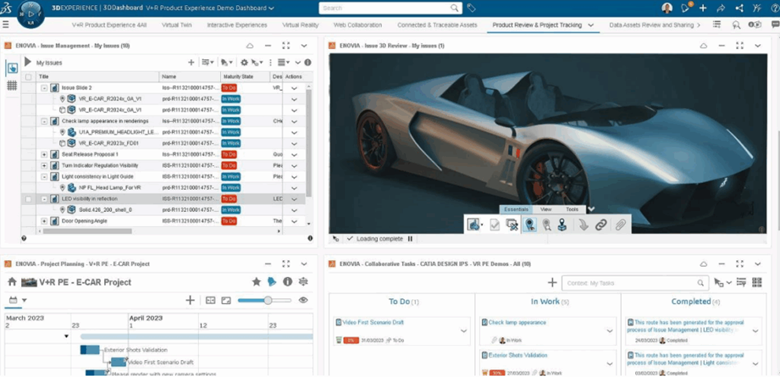

- Integrated Engineering: As IDX is on the 3DEXPERIENCE platform, engineering data can be loaded very easily without importing or exporting them, allowing users to access the whole product.

“IDX is really a fantastic class-A modeling tool and it’s all fully integrated on the 3DEXPERIENCE platform.” -Nick MCFERRAN, CATIA Design Industry Process Expert

Transitioning with ICEM Surf and IDX

The shift from traditional ICEM Surf software to IDX represents a transformative leap in modeling capabilities.

- Seamless Integration: IDX offers a cohesive interface with features familiar to ICEM Surf users, facilitating an easy transition while introducing advanced parametric and associative capabilities.

- Dynamic Modeling Environment: Features like multiple undos and smart updates streamline the modeling process, reducing time spent on corrections and enabling designers to focus on creativity and design intent.

- Collaboration and Customization: IDX encourages collaboration with its implementation on the 3DEXPERIENCE platform to remove silos and foster work between different teams. Through features like Natural Sketch for real-time markups or parametric editing for improvements, decision-making processes and iterations are easier and faster.

Conclusion

In industrial design and engineering, OEMs must continually innovate to stay ahead of the curve and effectively face significant challenges in surface modeling. Still, with online CAD software like CATIA and applications like ICEM Design Experience on the 3DEXPERIENCE platform, designers have the resources they need to overcome these obstacles.

By integrating this modern technology, which maintains flexibility and fosters collaboration, OEMs can navigate this complex landscape. They can create innovative and sustainable products, but also accelerate their class-A processes with Sub-D, Bezier, and NURBS integration, smart features and parametric associativity.

Embracing these advancements ensures that they remain competitive in today’s rapidly evolving market, ready to meet the ever-increasing expectations of customers and the demands of the future.

FAQ

1) What are the main challenges OEMs face in surface modeling today?

OEMs must balance design intent with technical constraints like draft angles, tooling directions, curvature analyses, and surface highlights. They also need to keep up with evolving surface refinement techniques and integrate sustainability early in the design process.

2) What modeling techniques are becoming essential for modern surface design?

Techniques such as Sub-D, Bezier, and NURBS modeling are increasingly important. They allow designers to explore sophisticated shapes and aesthetic design while retaining functional integrity. Also, the synergy with additive manufacturing opens up possibilities for more complex and creative designs.

3) What is ICEM Design Experience (IDX) and how does it improve class-A surface modeling?

ICEM Design Experience is a CATIA application dedicated to class-A surface modeling with enhanced precision and flexibility. Key features include parametric associativity (curves and dependent blends auto-update), organized model zones for focused editing, integrated visualization tools, and the ability to access engineering data directly on the 3DEXPERIENCE platform.

4) How does IDX make the transition from traditional ICEM Surf easier for modelers?

IDX provides a familiar interface for ICEM Surf users, but adds dynamic modeling capabilities such as multiple undos, smart updates, and strong parametric and associative mechanisms. It reduces manual corrections, streamlines workflows, and helps users focus more on design intent.

5) What benefits do companies gain by adopting ICEM Design Experience & surface modeling improvements?

Companies improve productivity, precision, and quality in surface design. They gain faster iterations, better integration between design and engineering, enhanced sustainability considerations, and maintain competitiveness in markets with rising expectations for both aesthetic and functional excellence.