Introduction

In today’s competitive manufacturing environment, few engineering teams operate within a single software ecosystem. Instead, they rely on a patchwork of platforms, vendors, and file formats, each contributing to the development of complex products. This multi-vendor reality makes effective CAD data management one of the most critical and challenging responsibilities for design teams worldwide.

Powerful PLM on The 3DEXPERIENCE platform paired with the time-tested utility of CATIA CAD, has become a strategic solution for managing this complexity. Together, they enable companies to organize, structure, and collaborate on CAD files, even when those files originate from third-party suppliers or are exchanged in neutral formats like STEP.

In this article, we explore why CAD data management is essential in a multi-CAD world and how our teams at Mecanica support manufacturers in building smarter, more resilient workflows.

The Challenge of Multi-Vendor CAD Environments

Modern product development rarely happens in isolation. Whether you’re building automotive components, consumer products, or industrial machinery, chances are your team interacts with suppliers, partners, and contractors who use different design tools. SOLIDWORKS, Creo, Siemens NX, and other CAD programs each have unique file structures and modeling techniques. As a result, the need for efficient CAD data management becomes more urgent as product complexity increases.

Without a clear strategy for CAD data management, teams risk version control problems, missing references, broken assemblies, and delayed time to market. Trying to convert files manually or rebuild features from scratch wastes valuable time and introduces errors. Engineering teams need a platform that can not only read and structure imported files but also preserve design intent and support reuse.

Why STEP Files Matter

STEP files (ISO 10303) are one of the most widely used neutral formats for 3D CAD data exchange. Their purpose is to provide a common language between different CAD platforms. When a supplier sends an assembly as a STEP file, it allows the receiving team to view, manipulate, and integrate that model regardless of which software was used to create it.

But simply opening a STEP file is not enough. Many systems import geometry but lose critical metadata, part structure, or assembly relationships. A poor import can turn an intelligent model into a static “dumb solid,” which limits reuse and makes downstream tasks like simulation or manufacturing prep more difficult.

Effective CAD data management means going beyond basic viewing. It requires intelligent import tools that understand how to structure a model, maintain its hierarchy, and enable collaboration across disciplines.

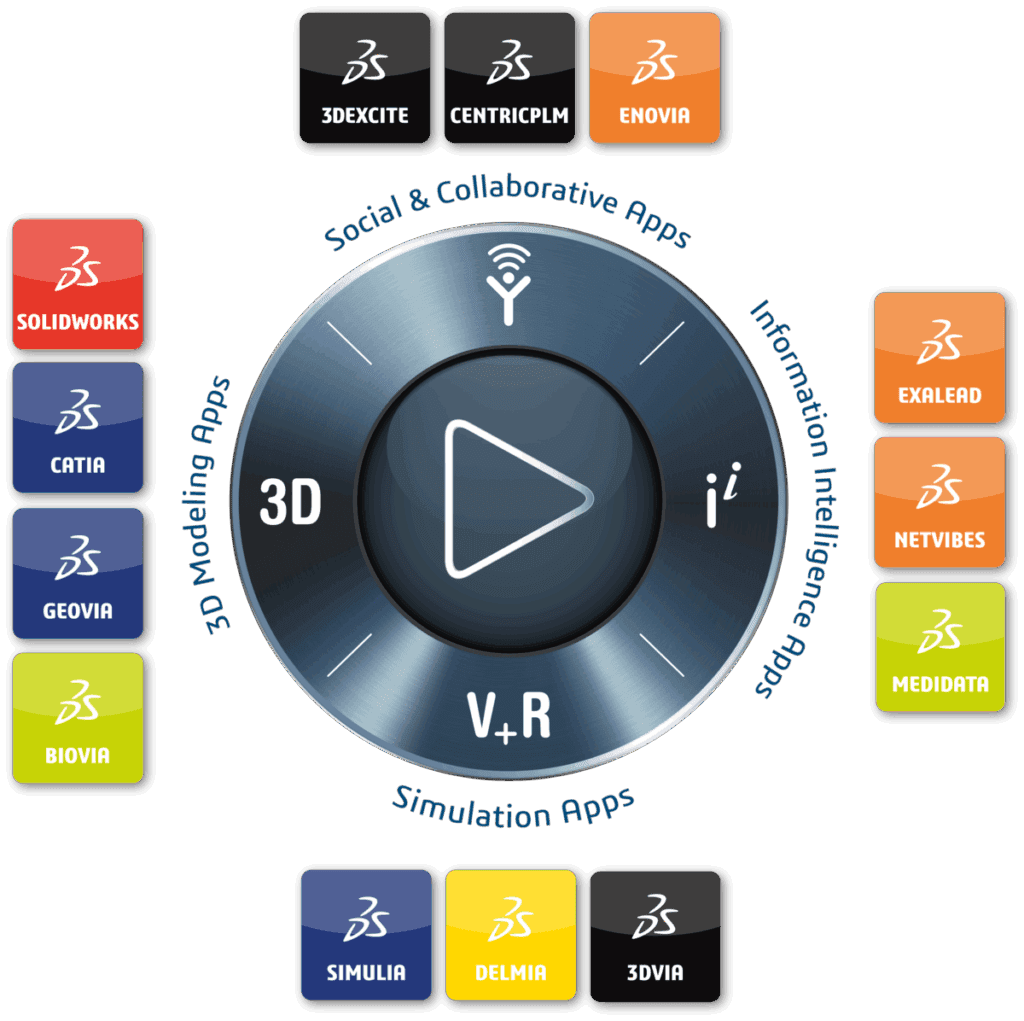

How the 3DEXPERIENCE Platform Solves the Problem

Dassault Systèmes’ 3DEXPERIENCE platform offers a unified environment for design, simulation, documentation, and collaboration. When integrated with CATIA V5, it becomes a powerful tool for CAD data management, especially in multi-vendor workflows.

Centralized Control with 3DEXPERIENCE

Where CATIA excels at file-level structuring, the 3DEXPERIENCE platform brings enterprise-level CAD data management. It offers tools for access control, version tracking, lifecycle management, and cross-functional collaboration.

For example, once a STEP file is imported and structured in CATIA, it can be saved and shared via 3DEXPERIENCE. Other stakeholders, such as manufacturing, quality assurance, or supply chain teams, can view and annotate the design. Engineers can work in parallel while maintaining a single source of truth.

This eliminates the need to send ZIP files or manage local file paths. All data resides on a secure, cloud-enabled platform that connects users in real time.

Scenarios Where 3DEXPERIENCE Makes a Difference

Supplier Integration: A Tier 1 supplier sends a STEP file of a sub-assembly. Instead of manually reverse engineering it, the design team imports the file into CATIA V5, reviews the product structure, and assigns metadata in 3DEXPERIENCE for internal traceability.

Design Review: A global team accesses a centralized model in 3DEXPERIENCE. Using built-in markup tools, they review the imported geometry, suggest modifications, and track changes across time zones.

Change Management: When a supplier sends a revised STEP file, the team compares the new version within 3DEXPERIENCE, identifies what’s changed, and updates affected parts without losing history.

Mecanica’s Role in Optimizing CAD Data Management

While the tools are powerful, the key to success lies in proper implementation and training. This is where Mecanica steps in. As an authorized Dassault Systèmes partner with decades of experience in advanced CAD tools, Mecanica helps engineering teams adopt best practices for CAD data management.

Onboarding and Training

We provide training programs that walk teams through importing, structuring, and reusing STEP files inside CATIA and 3DEXPERIENCE, and so much more. No matter where you are in your professional learning journey, we offer a learning pathway to help you reach your goals.

Every day, our training sessions help designers and engineers understand how to minimize rework, maintain references, and apply design intelligence even to non-native models.

Workflow Standardization

For companies that manage large volumes of supplier data, we can work alongside your internal teams to create standardized import workflows. These might include automated part numbering, metadata tagging, or lifecycle rules that align with internal processes.

Expert Support

Whether you’re onboarding new suppliers, migrating legacy data, or facing interoperability issues, Mecanica’s CAD consultants can help resolve roadblocks. They know how to bridge gaps between systems and ensure long-term scalability in your product development pipeline.

CAD Data Management Is the Foundation of Modern Product Development

As digital transformation continues to accelerate across industries, and as North America dives deeper into Industry 4.0, the ability to manage CAD data effectively will only become more important. CAD data management is no longer about simply organizing files. It is about enabling collaboration, protecting design intent, and supporting innovation at scale.

By combining the structured intelligence of CATIA with the collaborative backbone of the 3DEXPERIENCE platform, companies can take control of their product data, reduce rework, and unlock productivity across their entire engineering team.

Conclusion: One Platform, Infinite Possibilities

At Mecanica, we believe that CAD data management is not just a technical challenge. It is a strategic one. Companies that can organize, track, and collaborate across their CAD ecosystem are better positioned to bring innovative products to market, faster and with fewer errors.

Whether you are beginning to standardize supplier collaboration or preparing to scale your design operations across teams and locations, the 3DEXPERIENCE platform supported by Mecanica’s industry-leading expertise gives you the tools to lead. Let us help you streamline workflows, strengthen product development, and elevate your engineering capabilities.

Ready to evolve your CAD data management? Connect with our experts today.