Summary

Augmented reality (AR) and virtual reality (VR) have become important tools for engineers who work with complex 3D data. On the 3DEXPERIENCE platform, AR and VR provide new ways to explore, validate, and present designs across product development workflows. This article explains the differences between AR and VR and how they fit into modern engineering processes on the 3DEXPERIENCE. The goal is to examine today’s immersive technologies while exploring the possibilities they hold for the future. Let’s dive in!

Introduction

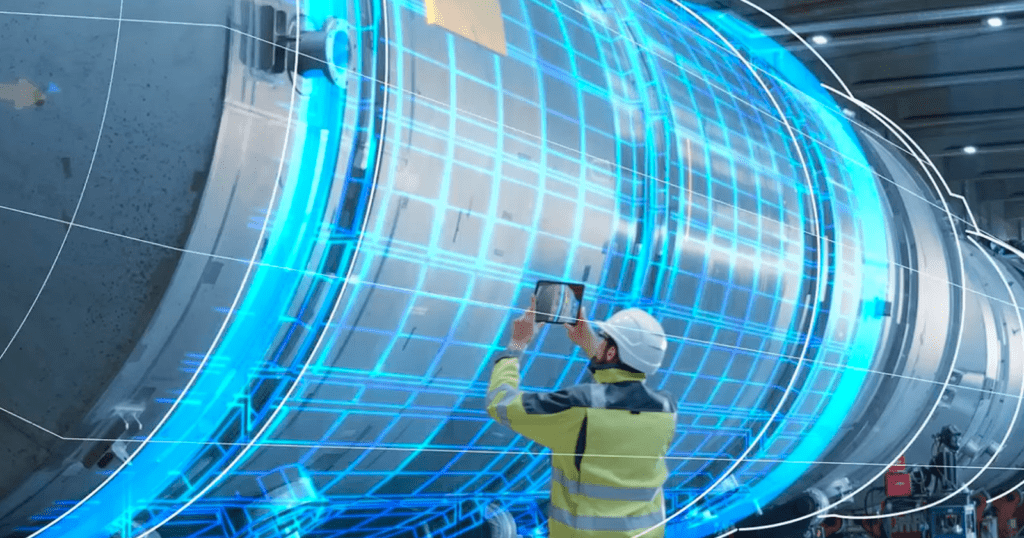

Immersive technology and experiences are no longer the dreams of science fiction. Today’s engineering teams are already leveraging augmented and virtual reality to understand 3D data in ways that traditional screens cannot support.

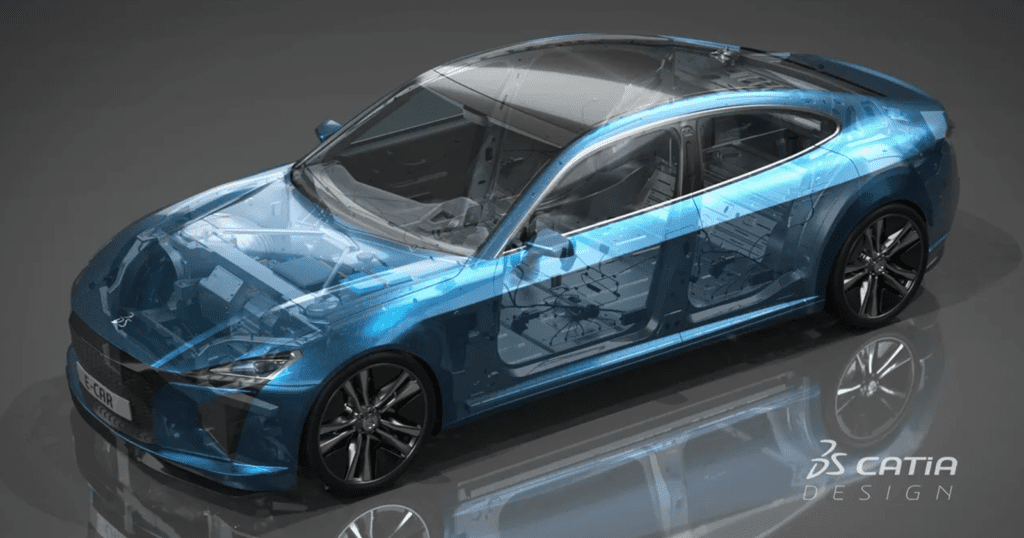

As products grow more complex and development cycles become more distributed, AR and VR help clarify geometry, ergonomics, space requirements, and assembly behavior. They bring depth to digital models produced with tools like CATIA’s Virtual + Real (V+R) Product Experience solutions and DELMIA Augmented Reality Experience, while also helping non-engineering stakeholders understand design intent early in the design process.

While AR and VR share similarities, their strengths differ.

Knowing where each excels helps teams choose the right immersive tool at the right time.

What AR and VR Mean in the Context of 3DEXPERIENCE

Although AR and VR are often mentioned together, they serve different needs. Augmented Reality (AR) overlays digital content onto the real world. Virtual Reality (VR) removes the physical world entirely and replaces it with a simulated environment.

Both approaches deepen understanding of geometry, but the nature of that understanding changes:

- AR keeps real-world context intact

- VR provides complete immersion

On the 3DEXPERIENCE platform, immersive tools pull directly from the unified data model used across design, simulation, and manufacturing planning. This helps reduce misinterpretation and supports continuity across teams.

❓Did you know? We’ve explored a similar topic in a previous blog, for further reading check out: Virtual Twin vs Digital Twin: What’s the Difference and Why It Matters in Engineering

Who Uses AR and VR on the 3DEXPERIENCE Platform

Immersive tools support a wide range of engineering and non-engineering roles. For example:

Designers and CAD Modelers

Use VR to explore form, surface quality, and spatial relationships at real scale.

Manufacturing Engineers

Use AR to evaluate equipment placement inside physical facilities and confirm operator access.

Process Planners

Use VR to visualize sequences, test access paths, and review fixture placement.

Maintenance and Service Teams

Use AR for step-by-step overlays directly on real equipment.

Stakeholders and Clients

Use VR for clear, intuitive design presentations during reviews or approvals.

Training Teams

Use immersive sessions to help new technicians understand workflows before entering the shop floor.

Each role benefits differently, but the common thread is clarity.

Where AR and VR Fit in 3DEXPERIENCE Workflows

Because the 3DEXPERIENCE connects design, simulation, and manufacturing, immersive experiences enhance multiple stages of the lifecycle.

Early Design and Review

VR supports full-scale evaluation of assembly behavior, space requirements, ergonomics, and hidden geometry. Teams can investigate issues early, often reducing the number of physical prototypes required.

Industrialization and Facility Planning

AR helps validate spatial constraints by overlaying digital assets onto real environments. A team can examine how a machine or workstation fits into an existing factory layout.

Simulation and Ergonomics

VR enhances DELMIA simulations by letting users step inside the results. Observing human interaction, motion paths, or process flow becomes more intuitive.

Maintenance and Service Planning

AR displays instructions or visual indicators directly on top of equipment. This increases clarity and reduces errors during complex tasks.

Cross Functional Collaboration

VR or AR sessions bring distributed teams together. Even when participants are remote, they can share the same spatial view of the design.

Across these stages, immersive tools move engineering work from flat interpretation to spatial understanding.

When to Use AR and When to Use VR

Choosing the right tool depends on the engineering question at hand.

AR Works Best When Context Matters

A team might use AR when validating how a new piece of equipment fits within a real facility. By keeping the real world visible, AR reveals constraints a screen cannot show.

VR Works Best When Immersion Is Needed

VR is ideal when the product does not yet exist physically. Teams can explore internal spaces, test visibility, confirm reachability, or evaluate accessibility.

Training, Planning, and Review

AR supports real equipment training, while VR supports high-risk or highly complex task exploration. Many organizations blend both approaches depending on the stage of development.

A strong workflow often moves back and forth between AR and VR as the design matures.

Why AR and VR Matter in Engineering Culture Today

Engineering work often involves interpreting dense 3D data, large assemblies, or multi-step processes. Immersive tools help teams understand information more clearly and more quickly.

They also help bridge communication gaps. Stakeholders who struggle with CAD viewers can still understand a product while standing inside a full-scale VR environment or viewing an AR overlay on real machinery.

It’s all about digital continuity. The 3DEXPERIENCE already keeps data connected from design through manufacturing. AR and VR extend this continuity by transforming digital content into spatial experiences.

The Future of Immersive Technology on the 3DEXPERIENCE

The next generation of immersive tools is likely to merge AR and VR rather than separate them. Mixed reality and spatial computing devices already support this evolution.

We’re already looking forward to:

- To-scale evaluations of assemblies anchored in physical space

- Real-time collaboration across immersive environments

- Integration with SIMULIA or DELMIA simulation results

- Multi-user engineering reviews inside shared spatial models

Conclusion: Choosing the Right Immersive Tool at the Right Time

AR and VR give engineering teams flexible ways to explore digital models on the 3DEXPERIENCE platform. AR connects digital information to real environments, while VR enables full immersion for detailed review. Used together, they provide a clearer understanding of geometry, assembly behavior, and operational context.

Teams that adopt immersive workflows gain stronger communication, faster decision cycles, and a more efficient path from concept to production.