Introduction: Where Data Continuity Breaks First

Engineering teams are no strangers to process improvement. Countless hours go into refining design standards, tightening review cycles, and smoothing out release procedures. Within the walls of a single team, things usually feel structured and under control. Files are organized. Expectations are clear. Workflows make sense. But that sense of order has a habit of breaking down the moment data needs to move beyond the team. The real problems rarely start inside one group.

They show up at the handoffs. Designs pass from engineering to manufacturing, where revisions are shared with suppliers, or where one team assumes another is working from the “latest” version. That’s where data continuity quietly unravels.

As products grow more complex, engineering work increasingly spans mechanical, electrical, simulation, software, and manufacturing disciplines. Each team may operate effectively on its own, but continuity breaks when data moves between them. Engineering managers see the symptoms clearly:

- conflicting versions,

- unclear ownership,

- Late discovery of issues,

- and growing friction during handoffs.

This article explains why data continuity breaks down between engineering teams and how digital engineering platforms prevent those breakdowns by providing shared structure, visibility, and governance across disciplines.

Why Team Boundaries Are the Weakest Point

Within a single team, informal knowledge often fills process gaps. Engineers know who owns which data, how reviews are handled, and what “done” means in practice. That understanding is rarely documented, but it works locally.

When work crosses team boundaries, those assumptions collapse.

One team may consider data released while another treats it as preliminary.

Metadata definitions differ.

Review expectations are interpreted differently.

These misalignments are rarely intentional, but they accumulate quickly as more teams interact. As organizations scale, the number of handoffs increases. Each handoff introduces risk. Without shared rules, data continuity becomes fragile and difficult to sustain.

Unclear Data Ownership Between Teams

A common source of continuity failure is unclear ownership. When multiple teams touch the same data, responsibility becomes ambiguous.

Engineering managers hear recurring questions.

- Who approves this change?

- Who updates downstream documentation?

- Who ensures manufacturing is using the correct version?

In disconnected environments, ownership is often managed through meetings, emails, or personal follow ups. These mechanisms do not scale and rarely provide visibility to everyone involved. Engineers hesitate or duplicate work to protect themselves when ownership is unclear.

Digital engineering platforms, like the 3DEXPERIENCE platform, clarify ownership by making it explicit. Data objects have defined owners, lifecycle states, and approval paths that are visible across teams.

Ownership becomes part of the system rather than a social agreement.

Workflow Misalignment Creates Hidden Delays

Even when teams use similar tools, they often follow different workflows. One team may require formal design reviews while another relies on informal peer checks. Lifecycle states may share names but carry different meanings.

When data moves between teams, these differences create friction. Engineers spend time reconciling expectations instead of advancing work. Delays emerge not because work is complex, but because processes do not align.

Digital platforms address this problem by enforcing shared workflow definitions. Teams retain flexibility in how they execute work, but the system ensures that key lifecycle states and transitions are consistent.

Engineers no longer need to interpret how another team operates.

Lack of Shared Visibility Between Disciplines

Limited visibility is another major contributor to continuity breakdowns. Engineers often lack insight into what other teams are working on or how changes affect downstream activities.

Without shared visibility, teams work in parallel but drift apart. Conflicts surface late, when they are more expensive to resolve and harder to trace back to their source.

A digital engineering platform provides shared visibility into data status, relationships, and changes. Engineers and managers can see how work connects across disciplines without relying on manual updates or status meetings.

This transparency supports proactive coordination rather than reactive correction.

Governance Breakdowns at Scale

As organizations grow, governance becomes harder to enforce consistently. Processes that worked for small teams begin to strain under scale.

Engineering managers often observe that rules exist but are applied inconsistently. Some teams follow formal change processes while others bypass them to maintain speed. Over time, exceptions become the norm.

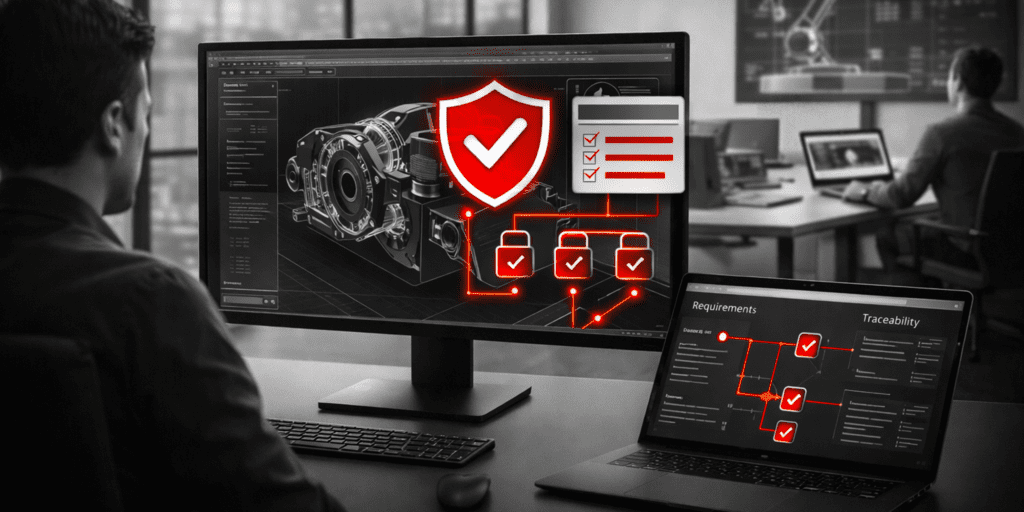

Digital engineering platforms support governance by embedding it into the workflow. Lifecycle rules, approvals, and traceability are enforced by the system rather than individual policing.

Governance becomes scalable because it is part of daily work.

How Digital Platforms Preserve Context Across Teams

The defining strength of a digital engineering platform is its ability to preserve context as data moves between teams.

Relationships between parts, assemblies, and documents remain intact. Changes are tracked in relation to impacted data. Approvals and lifecycle transitions are recorded as part of the data history rather than informal communication.

This preserved context allows teams to trust shared data. Engineers can understand not only what changed, but why it changed and who approved it.

Continuity shifts from a human responsibility to a system capability.

Balancing Standardization and Team Autonomy

Engineering managers often worry that shared platforms will force teams into identical workflows. In practice, effective platforms balance standardization and autonomy.

Teams can use role appropriate views and tools while operating on shared data.

The platform defines common rules for:

- Governance

- Traceability

- Lifecycle management

- Approvals and status changes

…without dictating how every task is performed. This balance allows teams to collaborate effectively without sacrificing discipline specific practices.

Early Warning Signs Managers Should Watch For

Continuity breakdowns rarely appear suddenly. They develop gradually.

- Warning signs include:

- Frequent clarification meetings

- Duplicated models

- Late discovery of conflicts

- Increasing reliance on spreadsheets or email to track status.

These symptoms indicate that systems are not providing sufficient structure at team boundaries. Digital platforms help address these issues by restoring clarity, ownership, and visibility before problems escalate.

Decision Framework for Engineering Managers

Engineering managers evaluating continuity issues can ask a few key questions.

- Is ownership of shared data explicit?

- Are lifecycle states understood consistently across teams?

- Can changes be traced end to end without manual effort?

- Do teams trust the system enough to collaborate early?

Clear answers indicate whether continuity is supported structurally or depends on individual effort.

Why Manual Coordination Fails at Scale

In early stages of growth, manual coordination often appears sufficient. Engineering managers rely on experienced individuals to bridge gaps between teams. Informal communication fills in missing process definitions.

As complexity increases, this approach becomes fragile. Knowledge concentrates in a few people, and continuity depends on availability rather than structure. When those individuals are unavailable, decisions stall and errors increase.

Digital platforms remove this dependency by institutionalizing coordination. The system provides continuity regardless of who is involved on a given day.

The Role of Engineering Managers in Platform Adoption

Engineering managers play a critical role in continuity outcomes. Platforms alone do not solve problems if teams are not aligned around shared use.

Managers must focus on clarifying ownership, reinforcing consistent lifecycle usage, and encouraging early collaboration. When managers treat the platform as the authoritative environment, teams follow suit.

Over time, the platform becomes part of how work is done rather than an additional tool.

Long Term Benefits of Structural Continuity

When continuity is structurally supported, organizations experience compounding benefits.

- Teams collaborate earlier.

- Errors surface sooner.

- Trust in shared data increases.

Engineering managers gain visibility without micromanagement. Decisions are made with better information, and scaling becomes more predictable. These benefits are difficult to achieve through disconnected tools alone.

Preparing Teams for Future Growth

Continuity challenges rarely disappear as organizations mature. New products, suppliers, and partners introduce additional complexity. Teams that rely on informal coordination struggle to adapt.

Digital engineering platforms provide a foundation that supports future growth. As new teams are added, they inherit existing governance and workflow structures. Continuity is maintained without reinventing processes.

For engineering managers, this preparation reduces risk and supports long term stability.

From Reactive Fixes to Proactive Systems

Many organizations address continuity problems reactively. Teams introduce additional checks, meetings, or documentation to compensate for system gaps. These fixes add overhead without addressing root causes.

Digital platforms enable a proactive approach. By embedding continuity into everyday workflows, problems are prevented rather than corrected after the fact. Engineering managers can focus on improvement instead of firefighting.

This shift marks the difference between managing complexity and being constrained by it.

Conclusion: Continuity Is a Structural Responsibility

Data continuity breakdowns between teams are rarely caused by individual behavior. They emerge from structural gaps in how data, workflows, and governance are managed across disciplines.

Digital engineering platforms like the 3DEXPERIENCE platform prevent these breakdowns by providing shared rules, visibility, and context. By treating continuity as a system responsibility, organizations reduce friction, improve collaboration, and scale engineering operations more effectively.