Introduction: When Integration Stops Scaling

Engineering teams often assume that connecting tools will solve coordination problems. CAD systems integrate with data management solutions. Collaboration platforms link to design environments. Information appears to move more smoothly than it did in the past, and on the surface, work seems better connected.

Yet many practicing engineers still struggle with missing context, unclear data status, and inconsistent workflows. Files move between systems, but understanding does not always follow. Engineers spend time verifying whether information can be trusted instead of focusing on design work. Small interruptions accumulate over the course of a day, slowing progress, increasing frustration, and introducing avoidable rework.

The root issue is not the quality of integrations. It is how engineering data is treated once it exists inside the environment. A digital engineering platform differs fundamentally from a set of connected tools because it manages data context, relationships, and workflows as part of a shared system rather than as optional additions layered on afterward.

This article explains what separates a true digital engineering platform from connected engineering tools and why that distinction matters for engineers working across teams.

Why Connected Tools Still Create Daily Friction

Integration focuses on moving data from one system to another. It ensures that files can be transferred, synchronized, or referenced across tools. What integration does not define is how that data should behave once it arrives.

In connected tool environments, engineers commonly encounter:

- duplicated files,

- inconsistent metadata,

- unclear ownership.

Even when integrations work as designed, engineers must still reconstruct context manually. They rely on naming conventions, spreadsheets, or informal conversations to understand whether a model is current, approved, or ready for use.

As teams grow and collaboration increases, these gaps become harder to manage. Engineers lose confidence in the system and compensate by keeping local copies, delaying collaboration, or performing additional checks before using shared data. Productivity suffers not because tools are missing, but because the environment does not provide consistent structure for everyday work.

What Defines a Digital Engineering Platform

A digital engineering platform provides a shared foundation for how engineering data is created, managed, and evolved across teams.

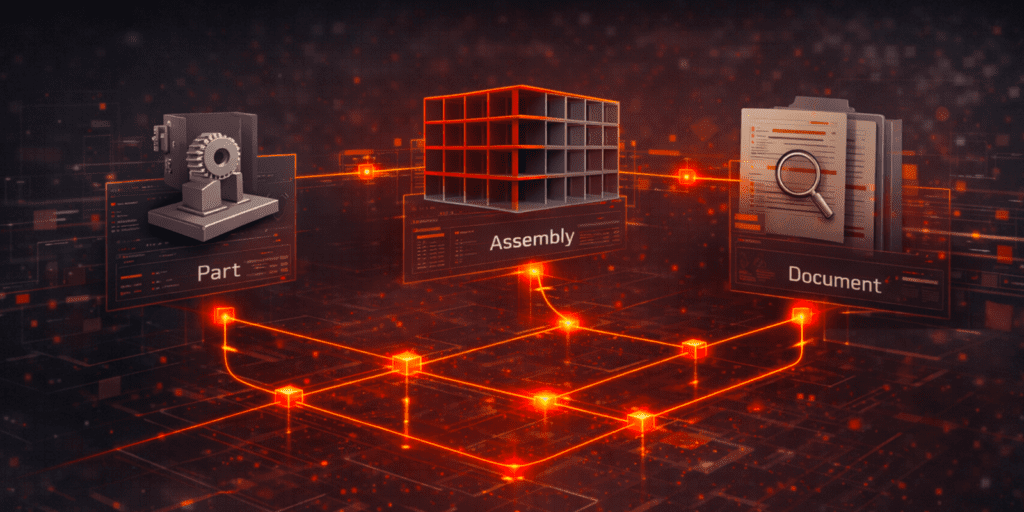

Rather than treating tools as independent systems linked by integrations, a platform establishes common rules for data behavior. It centralizes product data, standardizes lifecycle states, and maintains relationships between parts, assemblies, and documents regardless of which authoring tool is used.

This approach allows engineers to interact with data that already carries its meaning. Status, ownership, and relationships are visible without manual interpretation. The system supports engineers by design rather than relying on individual discipline or tribal knowledge.

The 3DEXPERIENCE platform is built around this principle. It connects design, collaboration, and data management within a single environment so engineers can work with confidence that their data remains consistent as it moves across teams.

Data Context Versus File Storage

One of the clearest differences between platforms and connected tools is how context is handled.

In file-centric environments, files are the primary unit of work. Context exists outside the file itself. Engineers must infer how a file relates to an assembly, whether it reflects current design intent, and what lifecycle state it holds. This interpretation often depends on experience, memory, or side conversations rather than explicit information.

In a digital engineering platform, context is explicit. Relationships between data elements are preserved. Metadata remains consistent across disciplines. Revision history is tied directly to workflow events and approvals rather than being inferred after the fact.

For practicing engineers, this difference shows up immediately in daily work. Instead of asking which file to use or whether a change has been approved, engineers can see that information directly in the system. The platform removes ambiguity by design, reducing misinterpretation and minimizing avoidable rework.

Workflow Consistency Is Designed In

Workflow inconsistency is one of the most common sources of frustration for engineers. When each team follows different processes, it becomes difficult to predict what happens next or who is responsible at each stage.

Connected tools often rely on external processes to manage workflow. Reviews are tracked through email. Status updates live in spreadsheets. Engineers must check multiple systems to understand progress, increasing cognitive load and interrupting focus.

A digital engineering platform embeds workflow behavior directly into the environment. Lifecycle states, review steps, and approvals follow defined rules that apply consistently across teams. Engineers can see where work stands and what actions are required without leaving the system.

This consistency reduces uncertainty, shortens feedback loops, and helps engineers move work forward with fewer interruptions and less rework.

Preserving Relationships Across Teams

Engineering data rarely exists in isolation. Parts relate to assemblies. Designs relate to requirements. Changes affect downstream processes such as manufacturing and validation.

In connected tool environments, these relationships often break at system boundaries. Engineers lose visibility into how their work connects to the broader product definition and how changes may impact other teams.

A digital engineering platform preserves relationships independently of individual tools. As data moves through design, validation, and collaboration, its structure remains intact. Engineers can understand impact, trace changes, and collaborate more effectively because context travels with the data.

This continuity supports cross-functional collaboration without forcing all teams into the same authoring tools or workflows.

Reducing Cognitive Load for Engineers

When systems do not provide structure, engineers carry that burden themselves. They remember which files are safe to use, which processes apply to which teams, and where information lives. Over time, this mental overhead becomes a hidden productivity cost.

A digital engineering platform reduces cognitive load by handling consistency centrally. Engineers spend less mental energy managing information and more energy solving engineering problems. The environment guides behavior without constant oversight, allowing engineers to work efficiently while maintaining consistency across teams.

This shift is subtle but important. Engineers are able to trust the system rather than compensate for it.

Workflow Consistency Across Growing Teams

As engineering organizations grow, maintaining consistent workflows becomes increasingly difficult. New teams are added, responsibilities shift, and informal processes that once worked begin to break down. Engineers experience this as uncertainty about which steps apply and how decisions are made across teams.

A digital engineering platform helps stabilize workflows as organizations scale. Because workflow behavior is defined at the system level, new teams adopt the same lifecycle states and review expectations without reinventing processes. Engineers benefit from predictability even as the organization evolves.

This consistency is especially important when work spans multiple disciplines or locations. Engineers can collaborate with confidence, knowing that shared data follows the same rules regardless of where or by whom it was created.

How Engineers Can Recognize Platform-Level Thinking

Practicing engineers can assess whether their environment operates as a platform or as connected tools by asking a few questions.

Does the system manage relationships or simply store files. Are workflows defined or improvised. Is data context preserved automatically. Can changes be traced without manual tracking.

Clear answers indicate whether the environment supports consistent engineering work or relies on individual effort to compensate for system gaps.

Conclusion: Why the Distinction Matters

As engineering work becomes more collaborative and distributed, integration alone is no longer sufficient.

A digital engineering platform provides the structure needed to maintain data context, workflow consistency, and trust across teams. By managing relationships and behavior at the system level, platforms reduce friction and allow engineers to focus on design rather than coordination.

Understanding this distinction helps engineers make sense of their daily challenges and clarifies why platform-based environments such as the 3DEXPERIENCE platform are increasingly central to modern engineering workflows.