Introduction

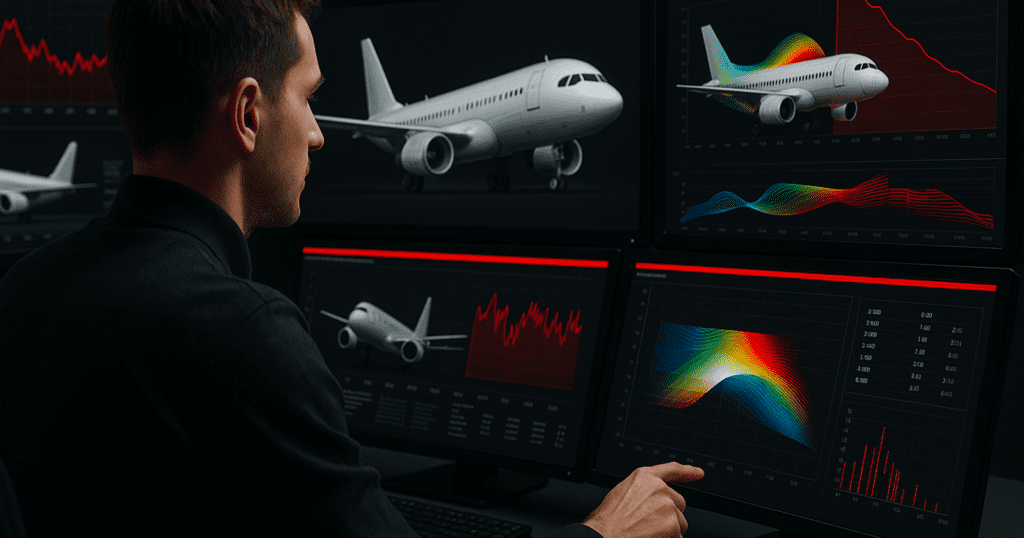

Aerospace engineering is a field defined by precision and innovation. Every design choice, material, and flight test has a direct impact on performance and safety. The digital twin in aerospace gives engineers the ability to simulate, predict, and improve every part of a system before an aircraft even takes off.

By creating a digital model that mirrors the physical aircraft, engineers can monitor performance, anticipate maintenance needs, and refine designs continuously. This evolving connection between physical systems and digital environments transforms how flight systems are developed and maintained.

In this article, we’ll explore how the digital twin in aerospace is improving safety, efficiency, and reliability.

What Is a Digital Twin in Aerospace?

A digital twin in aerospace is a living online replica of an aircraft, subsystem, or component that updates continuously through real-time data. It combines 3D CAD models, sensor information, and simulation tools to replicate how an aircraft behaves in actual conditions. Engineers can test and monitor performance digitally, avoiding disruptions to physical operations.

Unlike static simulations, the digital twin in aerospace evolves with every flight. When an engine runs, for example, its digital twin records temperature, pressure, and vibration data. This information helps engineers pinpoint areas of stress and predict maintenance needs long before failures occur. By maintaining a live connection between the real and digital versions, aerospace teams can make more informed, proactive decisions.

Why the Digital Twin in Aerospace Matters to the Industry

Aerospace projects are complex, expensive, and highly regulated. Traditional testing often requires physical prototypes, wind tunnels, and extensive post-flight analysis. While effective, these methods are time-consuming and resource heavy. The digital twin in aerospace provides a faster, more cost-efficient alternative that supports sustainability and accuracy.

By combining simulation results with live sensor feedback, engineers can test multiple configurations before manufacturing a single component. This reduces waste, shortens development timelines, and ensures design validation happens early. As aircraft systems become more advanced, the digital twin in aerospace helps maintain safety and compliance while supporting continuous innovation.

How the Digital Twin in Aerospace Improves Flight Safety

Safety remains the highest priority in aerospace engineering. The digital twin in aerospace enhances safety by continuously monitoring system behavior and predicting potential failures before they occur.

Early Detection of Failures

Real-time sensor data from engines, control systems, and landing gear feed into predictive models. If the system detects anomalies, such as pressure fluctuations or vibration spikes, it immediately flags them for inspection.

Virtual Emergency Simulations

The digital twin in aerospace makes it possible to run simulated emergencies, such as hydraulic failures or severe turbulence, safely in a digital environment. Engineers can test system resilience and adjust designs to prevent real-world incidents.

Simplified Certification Processes

Aerospace regulators are increasingly accepting digital evidence to support certification. Virtual validation through the digital twin in aerospace reduces the number of physical tests required, saving time while still meeting rigorous safety standards.

How the Digital Twin in Aerospace Drives Operational Efficiency

Operational efficiency covers every stage of an aircraft’s life cycle, from fuel consumption to maintenance. The digital twin in aerospace helps turn complex operational data into actionable insights.

Fuel Optimization

By analyzing data in real time, teams can determine optimal flight paths, adjust aerodynamic settings, and identify opportunities to reduce fuel consumption.

Predictive Maintenance

Instead of following fixed schedules, maintenance is now data driven. The digital twin in aerospace enables teams to service components based on actual performance metrics, reducing downtime and maximizing availability.

Lifecycle Visibility

Every part of an aircraft can be tracked throughout its life span. This ensures maintenance schedules reflect real usage rather than estimates, improving reliability while lowering long-term costs.

The Digital Twin in Aerospace Lifecycle: From Design to Takeoff

| Phase | How the Digital Twin in Aerospace Helps |

| Design | Tests aerodynamics, materials, and structural loads in virtual conditions. |

| Manufacturing | Monitors assembly accuracy and validates component integration. |

| In-Flight | Captures real-time performance data for continuous improvement. |

| Maintenance | Predicts part wear, schedules replacements, and supports compliance checks. |

This ongoing data cycle connects every stage of aircraft development. As engineers analyze performance, they feed results back into design models, creating a feedback loop that makes every new aircraft smarter than the last.

Engineering Tools That Power the Digital Twin in Aerospace

Building a digital twin in aerospace requires advanced software capable of managing vast amounts of multidisciplinary data. Tools such as CATIA, SIMULIA, and the 3DEXPERIENCE platform provide engineers with the unified digital environment needed for design, simulation, and lifecycle management.

Plus! The Mecanica team is here to help aerospace organizations implement and optimize these solutions. With decades of experience, our experts guide teams through training, integration, and data management to ensure seamless collaboration between design and operations.

With Mecanica’s support, companies can connect live performance data with digital models, fully realizing the value of the digital twin in aerospace for both design improvement and long-term maintenance.

The Future of the Digital Twin in Aerospace

The future of the digital twin in aerospace lies in artificial intelligence and sustainability. AI-driven analytics will make it possible for aircraft systems to adjust automatically, detect inefficiencies instantly, and recommend design improvements during flight.

As the industry focuses on greener aviation, the digital twin in aerospace will play a vital role in testing lightweight materials, optimizing aerodynamics, and evaluating alternative fuels.

Want more? 👉 Check out our previous blog that takes an in-depth look at how Digital Twin Technology is transforming aircraft maintenance.

Other emerging uses include cabin comfort optimization, autonomous flight simulation, and environmental monitoring, all supported by accurate digital models.

Conclusion

The digital twin in aerospace connects design, testing, and real-world airplane operation into one continuous learning cycle. It enhances safety, boosts efficiency, and lowers costs while helping teams innovate faster.

With advanced software like CATIA, SIMULIA, and 3DEXPERIENCE, supported by Mecanica’s engineering expertise, companies and engineers can rely on the digital twin in aerospace to design smarter, operate safer, and reach new heights in performance and sustainability.