Introduction

The terms digital twin and virtual twin often get used interchangeably, but they represent two distinct concepts in modern engineering. A digital twin reflects the current state of a physical object through real-world data, while a virtual twin creates an interactive, simulation-based environment to explore how a system behaves, even before it exists physically.

This article explores the differences between a Virtual twin vs Digital twin in engineering, explains how they complement each other, and highlights how Dassault Systèmes’ 3DEXPERIENCE platform brings both to life for better innovation, design, and performance.

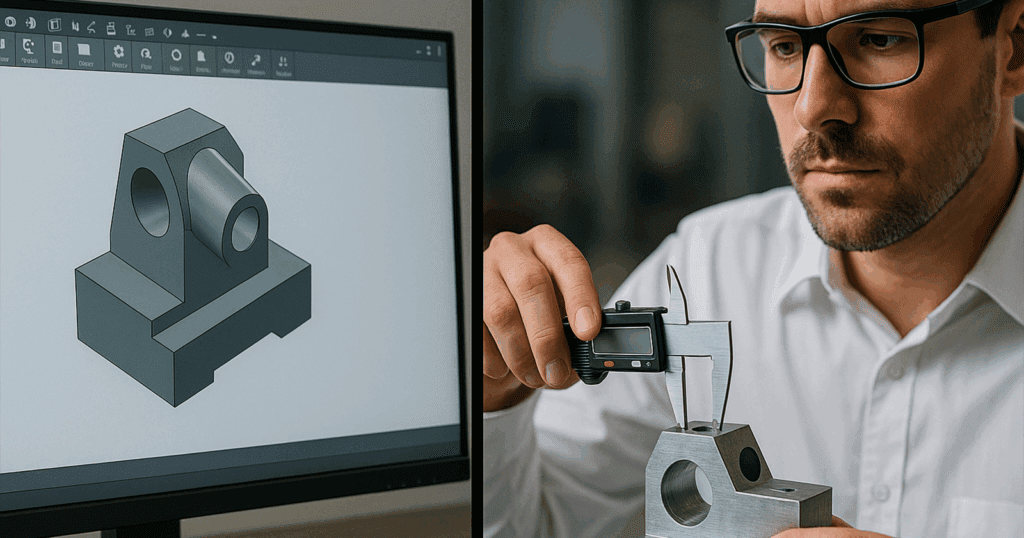

What Is a Digital Twin?

A digital twin is a digital representation of a real-world product, machine, or process that evolves in parallel with its physical counterpart. It relies on data from sensors and connected devices to reflect the actual performance, condition, and lifecycle of that object.

Key Characteristics

- Built from real-time or historical data gathered from the physical asset

- Reflects the current operational state or health of the product

- Enables predictive maintenance, fault detection, and performance optimization

Digital twins are particularly powerful in industries such as manufacturing, aerospace, energy, and automotive, where continuous feedback loops improve reliability and reduce downtime.

What Is a Virtual Twin?

A virtual twin, on the other hand, is a comprehensive digital model that integrates simulation, design, data, and collaboration into one dynamic environment. Unlike a digital twin, a virtual twin doesn’t need a physical product to exist first and can simulate before production even begins.

Key Characteristics

- Simulates physical behaviors, materials, and interactions with complete accuracy

- Supports testing “what if” scenarios and design changes in real time

- Allows multi-disciplinary teams to collaborate and iterate virtually before building anything

In practice, a virtual twin is not just a representation, it’s a full experience of how a product will perform under various real-world conditions.

Virtual twin vs Digital twin: Key Differences

While both technologies are powerful, their purposes diverge. Understanding these differences helps teams choose the right tool for each stage of the engineering lifecycle.

| Feature | Digital Twin | Virtual Twin |

|---|---|---|

| Purpose | Monitor and analyze real assets | Design, simulate, and optimize new concepts |

| Physical product? | Yes | Not necessarily |

| Data sources | Sensor data from the real world | Simulated data and model parameters |

| Focus | Present and past performance | Future scenarios and possibilities |

| Collaboration | Primarily diagnostic | Highly collaborative and creative |

How Each One Fits in the Engineering Workflow

The digital twin and virtual twin are complementary tools used at different moments in the lifecycle of a product.

When to Use a Digital Twin

- To monitor real-world assets in factories or vehicles

- To analyze performance through IoT data

- To predict failures and schedule maintenance efficiently

When to Use a Virtual Twin

- During concept design and development phases

- To test alternative designs or materials before physical prototyping

- To simulate production lines and workflows for optimization

Often, a virtual twin comes first, enabling engineers to innovate safely in a digital sandbox. Once the product exists, it can evolve into a digital twin, continuously learning from physical data to improve the next iteration.

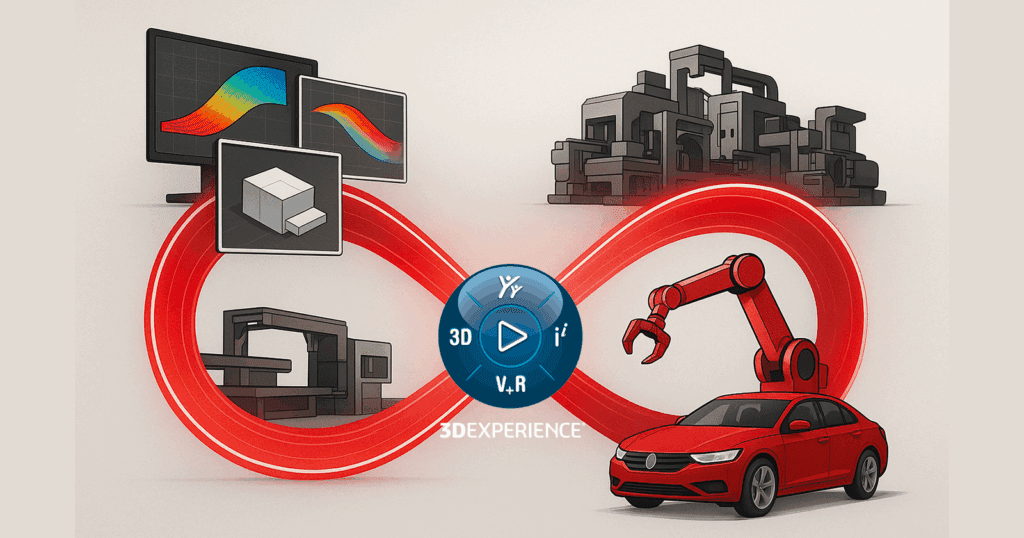

How the 3DEXPERIENCE Platform Brings Both to Life

Dassault Systèmes’ 3DEXPERIENCE platform uniquely integrates the digital and virtual twin worlds into one collaborative ecosystem. It enables engineers, designers, and manufacturers to share a single, data-driven environment where design, simulation, production, and performance are all connected.

Powering Digital Twins

- Captures and visualizes real-time data from physical assets

- Tracks system performance using IoT connectivity and dashboards

- Provides insights for maintenance, energy savings, and process optimization

Powering Virtual Twins

- Combines CAD, simulation, and PLM tools on a single platform

- Enables structural, thermal, and fluid simulations through physics-based modeling

- Allows immersive design reviews through tools like 3DPlay and 3DSwym

By uniting both types of twins under one data model, 3DEXPERIENCE ensures a continuous loop of learning between design, production, and real-world performance.

Why the Difference Matters

Understanding a Virtual twin vs Digital twin isn’t just semantics, it’s a matter of strategy. In engineering, each twin type delivers unique value.

Virtual twins let teams experiment safely, reducing prototyping costs and improving innovation speed. Digital twins ensure assets remain efficient, reliable, and easy to maintain after deployment. Together, they close the gap between concept and operation, transforming the way products evolve over time.

This synergy helps organizations move from reactive problem-solving to proactive, data-driven engineering.

Conclusion

Virtual twins and digital twins aren’t rivals. They are two halves of a single transformation cycle. A virtual twin gives engineers the freedom to imagine, simulate, and refine ideas. A digital twin ensures those ideas perform as expected once they’re built. Together, they create a feedback system that improves products, processes, and sustainability across industries.

Dassault Systèmes’ 3DEXPERIENCE platform bridges both worlds, giving engineers and manufacturers the ability to innovate with confidence from design to operation.

If your organization is exploring how to bring virtual and digital twin strategies into your workflows, the experts at Mecanica can help guide your transition with the right technology and expertise. Reach out today!