Introduction

Product lifecycle management (PLM) is no longer just about organizing CAD files or tracking revisions. It’s about connecting people, processes, and data in a unified ecosystem that drives measurable business value. ENOVIA PLM goes beyond traditional lifecycle systems by offering configurable tools for collaboration, compliance, project management, and sustainability, all integrated on the 3DEXPERIENCE platform.

We’ve explored ENOIVA before, s a portfolio of tools and the value it brings to design and production teams.

👉 If you missed it, check out our previous ENOVIA blog here.

But, what specific capabilities actually drive those benefits?

This article takes a deep dive into ENOVIA PLM capabilities, showing how this portfolio simplifies lifecycle management while giving organizations the flexibility to innovate faster and smarter.

Why PLM Needs More Than File Management

PLM has historically been equated with version control or document storage. While those functions remain important, they only scratch the surface of what’s needed today. Global supply chains, distributed teams, regulatory pressures, and sustainability goals demand a more comprehensive approach.

ENOVIA PLM addresses these challenges by embedding lifecycle management into every part of the product journey. Instead of treating PLM as a supporting system, ENOVIA becomes the backbone of decision-making across the business.

Core Capabilities of ENOVIA PLM

To understand what makes the platform stand out, it’s worth exploring its core modules and capabilities. Each is designed to eliminate silos, increase traceability, and support innovation at scale.

Product Data Management

ENOVIA PLM centralizes CAD files, BOMs, specifications, and project documents into a secure, single source of truth. Teams no longer waste time chasing down the “latest version.” Instead, data is instantly accessible in context, reducing duplication and errors.

Project and Portfolio Management

Built-in dashboards allow leaders to plan, assign, and track tasks directly within the system. Every milestone links to deliverables, ensuring accountability and visibility without relying on disconnected tools.

Requirements Management

From customer specifications to regulatory standards, ENOVIA PLM captures requirements and ties them directly to design elements, test results, and validations. This end-to-end linkage makes audits smoother and ensures nothing is missed when requirements shift.

Change and Configuration Management

Engineering Change Requests (ECRs) and Engineering Change Orders (ECOs) are simplified with automated workflows. Stakeholders are notified instantly, and changes are logged against affected parts and documents. Configuration management ensures each product variant is properly documented and controlled.

Compliance Management

Instead of treating compliance as an afterthought, ENOVIA PLM embeds it into the lifecycle. From environmental regulations to industry certifications, compliance data is tracked, documented, and tied to product records. This reduces risk and protects organizations from costly non-compliance.

Collaboration and Social Innovation

Through the 3DEXPERIENCE platform, ENOVIA brings contextual collaboration into the heart of projects. Comments, discussions, and decisions are linked directly to models or tasks, eliminating email chains and disconnected messaging.

Digital Continuity and the “Single Version of Truth”

One of ENOVIA PLM’s greatest strengths is digital continuity: the ability to connect data seamlessly across the entire lifecycle. From early CAD sketches to simulation outputs and manufacturing instructions, all information is linked in a continuous digital thread.

This continuity means:

- No lost data during handoffs.

- Immediate visibility into downstream impacts of design changes.

- The ability to trace product evolution decades into its lifecycle.

For industries like aerospace, automotive, and medical devices, this isn’t just convenient — it’s essential.

Integration With the 3DEXPERIENCE Platform

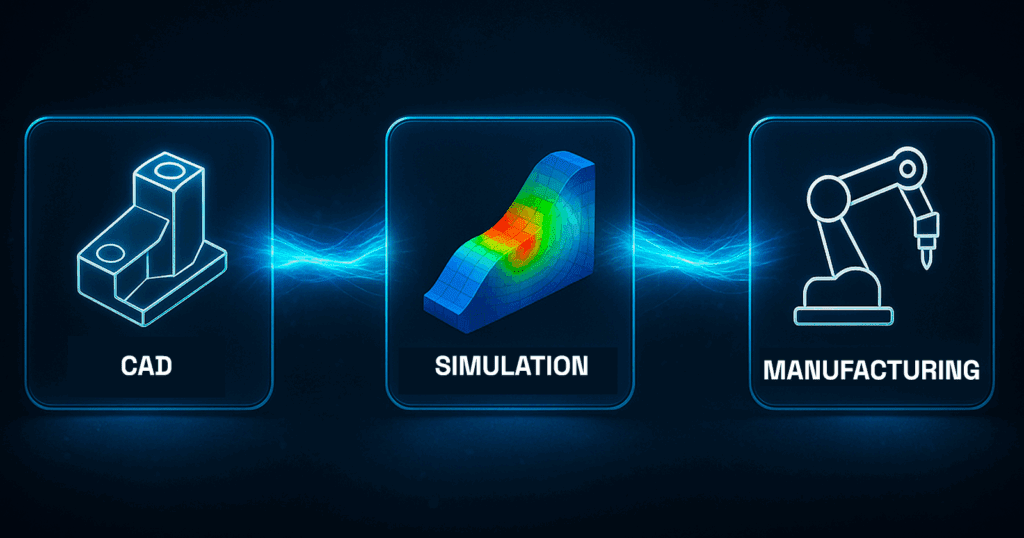

ENOVIA PLM doesn’t exist in isolation. Its integration with Dassault Systèmes’ 3DEXPERIENCE platform means it connects seamlessly with applications like CATIA, SIMULIA, and DELMIA.

Design Integration: Engineers can check in/out CAD files directly from CATIA or SOLIDWORKS with full revision control.

Simulation Integration: Results from SIMULIA are stored in the same environment, ensuring traceability and accessibility.

Manufacturing Integration: DELMIA manufacturing plans link directly to product data, so production is always aligned with design intent.

This ecosystem eliminates the need for disconnected software and ensures every decision is based on the same set of data.

Diving Deeper: Real-World Use Cases

How does this look in practice? Here are examples of ENOVIA PLM in action across industries:

Automotive: Global engineering teams coordinate new vehicle platforms while maintaining compliance with emissions and safety standards. ENOVIA PLM ensures all stakeholders work from one version of product truth, accelerating launches and reducing recalls.

Aerospace & Defense: Complex assemblies are tracked with full traceability from requirements to parts, ensuring readiness for regulatory audits. Engineers, suppliers, and inspectors all access the same records, cutting delays and ensuring safety.

Consumer Goods: Design teams collaborate with suppliers in real time, reducing time-to-market for seasonal launches. With ENOVIA PLM, marketing, supply chain, and design stay aligned on fast-moving projects.

Medical Devices: Compliance-driven design requires full audit trails. ENOVIA PLM provides the end-to-end traceability needed for FDA or ISO certification, while supporting innovation in competitive markets.

Each case highlights that ENOVIA delivers not just oversight, but a platform for proactive innovation and risk reduction.

The Future of PLM: AI, Cloud, and Sustainability

While ENOVIA PLM already simplifies lifecycle management today, its roadmap points toward even more transformative capabilities.

Artificial Intelligence: Machine learning tools within ENOVIA are being developed to predict project risks, optimize resource allocation, and recommend design improvements.

Cloud-First Flexibility: ENOVIA PLM on the 3DEXPERIENCE platform allows organizations to scale quickly without complex infrastructure investments. Cloud deployment also ensures remote teams can access tools securely from anywhere.

Sustainability Analytics: ENOVIA expands its ability to track environmental impacts. From material sourcing to end-of-life planning, sustainability data is integrated into the lifecycle, helping organizations meet both regulatory and ethical standards.

👉 We’ve explored the sustainability benefits of ENOVIA before! Check it out here.

This forward-looking approach ensures ENOVIA PLM remains not just relevant, but strategic, in shaping the next decade of product innovation.

Business Impact: From Engineering to Strategy

By diving deeper into the tool, it becomes clear that ENOVIA’s value isn’t confined to engineering. Executives gain insight into costs and risks, supply chain managers can predict delays, and quality teams can trace compliance.

Benefits of ENOVIA PLM include:

- Reduced time-to-market through streamlined processes.

- Lower operational costs by cutting duplication.

- Improved compliance confidence with embedded audit trails.

- Support for sustainability initiatives through better material tracking.

- Enhanced competitiveness with AI-driven insights and cloud scalability.

The result? ENOVIA PLM transforms lifecycle management from a technical system into a driver of agility and long-term business growth.

Conclusion

For companies looking to push beyond the basics of lifecycle management, ENOVIA PLM offers far more than project dashboards and version control. By embedding requirements, compliance, change management, and digital continuity into a single platform, ENOVIA PLM simplifies lifecycle management at scale.

Even the best tools need expert implementation. Mecanica helps organizations tailor ENOVIA PLM to their specific workflows, ensuring adoption is smooth and ROI is maximized. With decades of experience in engineering and digital transformation, Mecanica acts as a trusted partner in your PLM journey.