Abstract

Sustainability is no longer optional in today’s manufacturing world. Customers, regulators, and industry leaders expect companies to innovate while reducing waste, conserving resources, and complying with environmental standards. To meet these demands, organizations need more than traditional design tools; they need a digital backbone that connects data, processes, and teams.

ENOVIA provides exactly that. As part of the 3DEXPERIENCE platform, it enables sustainable digital manufacturing by embedding eco-conscious decision-making throughout the product lifecycle. This article explores how ENOVIA sustainable digital manufacturing empowers organizations to align innovation with responsibility, ensuring that progress doesn’t come at the expense of the planet.

The Shift Toward Sustainable Digital Manufacturing

Manufacturing has long been associated with resource-intensive processes. From sourcing raw materials to managing supply chains and production lines, companies face growing pressure to reduce their environmental impact. Stakeholders, from consumers to shareholders, are demanding transparency and accountability, and they expect companies to demonstrate measurable progress on sustainability goals.

This shift isn’t just about reputation management. Governments worldwide are enacting stricter regulations on carbon emissions, material sourcing, and waste management. Non-compliance can result in fines, supply chain disruptions, or exclusion from international markets. To stay competitive, manufacturers need tools that integrate sustainability into everyday operations.

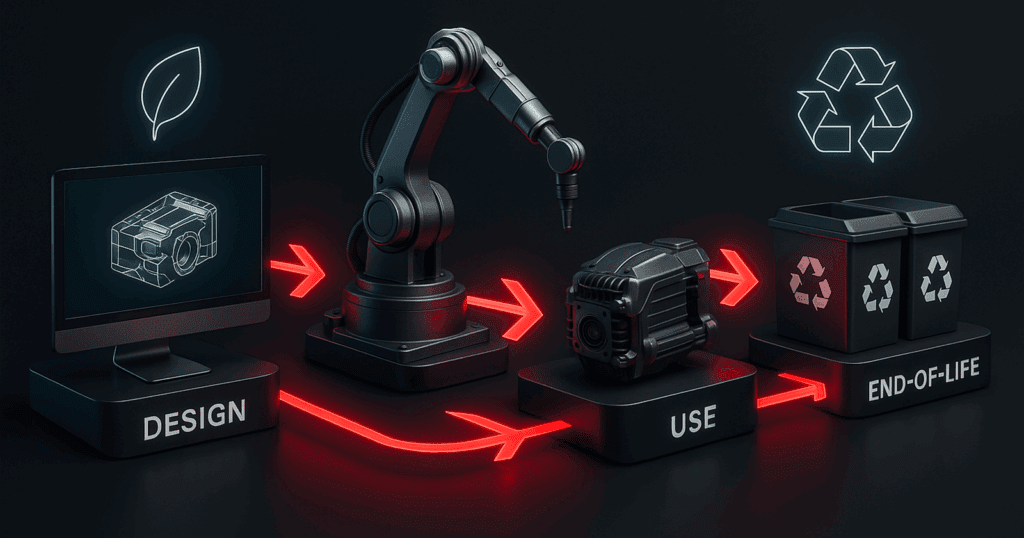

Digital manufacturing addresses this by providing visibility and control across the product lifecycle. By digitizing processes, companies can track materials, evaluate energy use, and assess environmental impacts with greater accuracy.

ENOVIA takes this further, enabling sustainability to become a design parameter rather than an afterthought.

ENOVIA as the Backbone of Sustainable Operations

ENOVIA provides a unified environment where requirements, product data, and processes converge. This centralized approach transforms sustainability from an external mandate into a built-in capability.

Lifecycle Visibility

ENOVIA allows teams to visualize the environmental footprint of a product from concept to end-of-life. Designers can assess the impact of materials and processes early, making sustainability part of the initial blueprint.

Integrated Compliance

With varying environmental standards across regions, compliance can be a moving target. ENOVIA integrates regulatory frameworks, helping companies confirm that designs meet requirements before they reach production.

Efficient Collaboration

Sustainability requires input from diverse stakeholders. ENOVIA enables cross-functional collaboration in one digital workspace, minimizing duplication, reducing unnecessary revisions, and accelerating innovation cycles.

Data-Driven Insights

Real-time analytics in ENOVIA highlight inefficiencies and resource consumption patterns. Teams can act on this data to reduce emissions, conserve energy, and identify new opportunities for circular design.

By embedding sustainability into decision-making, ENOVIA ensures that every project aligns with both business and environmental goals.

Driving Change with ENOVIA Sustainable Digital Manufacturing

The real power of ENOVIA sustainable digital manufacturing lies in how it operationalizes sustainability across the lifecycle.

Eco-Conscious Design

Design decisions account for the majority of a product’s environmental impact. ENOVIA equips teams with tools to analyze materials and processes before they are finalized. For instance, a design team can compare aluminum with recycled composites, weighing strength, cost, and environmental benefits within the same interface.

This reduces the risk of late-stage rework and ensures sustainability targets are met from day one.

Smarter Supply Chains

Supply chains are often the largest contributors to environmental impact. ENOVIA brings suppliers into the digital ecosystem, improving transparency and traceability. Manufacturers can prioritize suppliers with verified low-carbon practices or align sourcing strategies with global sustainability frameworks.

The result is a more resilient supply chain that balances cost efficiency with eco-conscious choices.

Closed-Loop Feedback

Products generate valuable data during use. ENOVIA captures this information and feeds it back into the design process, creating a closed loop that drives continuous improvement. A hypothetical automotive OEM, for example, could monitor vehicle performance data in real-world conditions and apply insights to design lighter, more efficient models, reducing both energy consumption and waste.

Real-World Applications Across Industries

ENOVIA’s flexibility makes it applicable across industries, each with its own sustainability challenges and opportunities.

Aerospace: Airlines and manufacturers use ENOVIA to model lighter aircraft components, reducing fuel consumption and emissions. Built-in compliance tools help ensure adherence to strict aviation regulations while advancing eco-friendly design.

Automotive: Automakers leverage ENOVIA to evaluate lifecycle impacts as they transition toward electrification. From battery sourcing to end-of-life recycling, ENOVIA helps integrate sustainability into the entire mobility ecosystem.

Industrial Equipment: Heavy equipment manufacturers use ENOVIA to optimize maintenance schedules, extending machine lifespans. This reduces the frequency of replacements, saving resources and energy.

Consumer Goods: Packaging design teams employ ENOVIA to test recyclable materials, ensuring compliance with local recycling laws while meeting consumer demand for eco-friendly products.

Why Sustainability Requires Collaboration

Sustainability is not confined to a single department. It requires collaboration across the enterprise. Engineers, supply chain managers, compliance officers, and executives must work toward shared objectives. ENOVIA makes this possible by:

Aligning Goals: Sustainability metrics are integrated into project dashboards, ensuring everyone works toward measurable targets.

Providing Transparency: With one source of truth, stakeholders can make decisions with confidence, supported by accurate and up-to-date data.

Enabling Accountability: Progress is tracked and visible, turning sustainability promises into verifiable outcomes.

By embedding collaboration into the platform, ENOVIA helps create a culture where sustainability is everyone’s responsibility.

The Business Case for Sustainability

Sustainability isn’t just good for the planet. It’s good for business!

Cost Savings: Energy-efficient processes and reduced waste lead directly to lower operating expenses.

Faster Time-to-Market: Integrated compliance and streamlined collaboration reduce delays, allowing products to launch sooner.

Stronger Reputation: Brands with credible sustainability practices build trust with customers, investors, and regulators.

Resilience: A sustainable supply chain is less vulnerable to disruptions, from raw material shortages to geopolitical instability.

The ROI of sustainability extends beyond environmental performance, it strengthens competitiveness and ensures long-term viability.

Future Trends in Sustainable Digital Manufacturing

Looking ahead, sustainability in manufacturing will continue to evolve. ENOVIA is positioned to support emerging trends such as:

Circular Economy Models: Designing products for reuse, recycling, and regeneration will become standard. ENOVIA helps track materials across multiple lifecycles.

Integration with Digital Twins: By simulating real-world performance, digital twins allow companies to test sustainability strategies virtually before implementation.

AI-Driven Insights: Artificial intelligence will enhance ENOVIA’s ability to recommend eco-friendly design alternatives and predict supply chain risks.

Conclusion: A Smarter Path Forward

Sustainable manufacturing is about more than reducing impact. It’s about building resilience, competitiveness, and trust. With ENOVIA, manufacturers gain a digital platform that embeds sustainability into every decision, every process, and every product lifecycle.

Ready to align your innovation strategy with eco-conscious manufacturing? Connect with Mecanica today to explore how ENOVIA sustainable digital manufacturing can transform your operations.