Introduction

Structural engineering and construction industries are undergoing rapid change. Traditional project workflows often struggle with delays, inefficiencies, and sustainability concerns. Modular construction offers a faster, smarter alternative — but it demands precision, collaboration, and advanced digital tools to succeed. CATIA structural engineering solutions provide engineers and builders with the ability to model, simulate, and coordinate modular workflows seamlessly. This article explores how CATIA supports structural engineering and modular construction, enabling firms to build efficiently, sustainably, and with greater confidence.

Industry Challenges in Modular Construction

The promise of modular construction lies in speed and repeatability, but execution is not always straightforward. Teams face persistent challenges:

- Complexity in large-scale projects: Prefabricated modules must fit together precisely, and design inconsistencies can cause costly delays on site.

- Design-to-fabrication gaps: Traditional CAD tools sometimes lack the intelligence to directly inform fabrication, creating disconnects between engineering intent and shop floor execution.

- Cross-disciplinary coordination: Architects, engineers, and contractors often work in silos, which increases the risk of clashes, design conflicts, and rework.

Without digital precision and robust collaboration, modular construction cannot reach its full potential.

CATIA’s Role in Structural Engineering

CATIA brings proven design and engineering capabilities to the world of structural engineering. At its core, CATIA structural engineering tools allow teams to:

- Develop highly detailed 3D models with precise geometry.

- Embed material properties, loads, and tolerances into the design environment.

- Simulate structural performance under real-world conditions.

This ensures that every design decision is informed, validated, and ready to move seamlessly into construction workflows. For structural engineers, CATIA transforms the traditional CAD environment into a collaborative and data-rich workspace where decisions are backed by simulation and integrated with downstream processes.

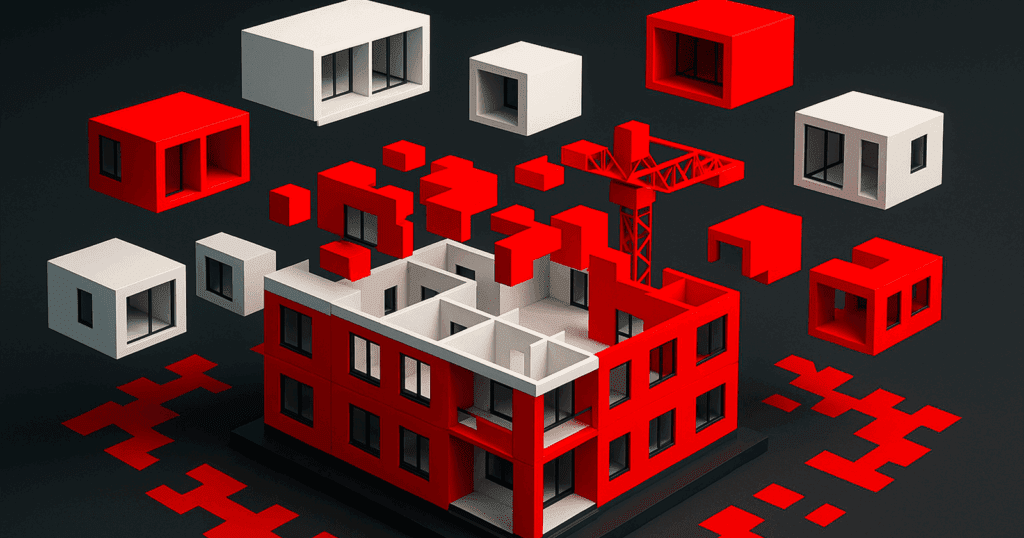

Modular Construction Workflows with CATIA

One of the most powerful applications of CATIA is in modular construction. Prefabricated modules demand accuracy and consistency, qualities CATIA is built to support.

With CATIA structural engineering:

- Standardization becomes straightforward. Modular elements such as walls, floor slabs, and structural frames can be designed once, validated, and reused across multiple projects.

- Clash detection prevents costly mistakes. CATIA highlights potential conflicts between structural, mechanical, and architectural systems before fabrication begins.

- Iterative design is accelerated. Teams can test multiple design variations quickly, ensuring that efficiency and safety standards are always met.

Step-by-Step Workflow Example

To better understand the benefits of CATIA structural engineering, consider a modular apartment building project:

- Design Phase: Engineers model structural elements such as beams, columns, and floor panels in CATIA, embedding material specifications and load data.

- Simulation Phase: The team runs stress tests on prefabricated modules, ensuring safety standards are met before fabrication begins.

- Fabrication Planning: CATIA data flows directly to manufacturing teams, who use the validated models to produce steel frames and concrete panels with precision.

- Logistics Coordination: Modules are packaged and shipped to the site with digital assembly instructions attached.

- On-Site Assembly: Construction crews use CATIA’s clash detection outputs to ensure seamless installation, reducing delays and rework.

This end-to-end workflow demonstrates how CATIA structural engineering closes the gap between design intent and construction reality.

Real-World Use Cases

CATIA’s versatility makes it applicable across diverse structural engineering projects:

Infrastructure Projects

For bridges, rail stations, and other complex infrastructure, CATIA structural engineering enables modular prefabrication of components that are easier to transport, assemble, and maintain.

Residential and Commercial Buildings

Prefabricated housing and commercial structures benefit from CATIA’s precise modeling, which ensures modules align correctly on site. This reduces costly downtime and accelerates project delivery.

Industrial Facilities

Modular approaches to warehouses and manufacturing plants demand large-scale repeatability. CATIA supports these needs by providing the tools to validate performance and optimize designs before construction begins.

Fabricator Hand-off Scenario

In modular projects, one of the biggest risks is misalignment between design and fabrication. A structural engineering team using CATIA structural engineering can export fully annotated digital models that include precise material properties, hole placements, and tolerance data.

Instead of interpreting 2D drawings, fabricators receive a complete 3D dataset that guides machine tools directly. As a result:

- Steel frames fit together without field adjustments.

- Cut lengths and weld placements are accurate on the first pass.

- Production waste is reduced because rework is minimized.

This digital handoff is a cornerstone of efficiency and one of the strongest advantages of adopting CATIA structural engineering for modular workflows.

Efficiency and Sustainability Benefits

Efficiency and sustainability are often linked, and CATIA provides value in both areas.

- Reduced material waste: By simulating assemblies in detail, CATIA helps minimize errors that lead to scrap or redesign.

- Lower energy use: Optimized modular design reduces the need for on-site adjustments, lowering equipment use and energy costs.

- Sustainable workflows: CATIA supports eco-conscious choices in materials, load optimization, and lifecycle planning.

With CATIA structural engineering, modular construction becomes not just faster but also more environmentally responsible.

Collaboration on the 3DEXPERIENCE Platform

Modular projects require constant communication between stakeholders. CATIA, when used on the 3DEXPERIENCE platform, offers a shared digital environment that breaks down silos.

- Architects and engineers work from the same live model.

- Contractors access accurate fabrication-ready data directly.

- Project managers track progress in real time with complete visibility.

This level of collaboration ensures that everyone is aligned, reducing costly rework and ensuring that modular projects are executed smoothly.

Strategic Advantages for Firms

Adopting CATIA for structural engineering and modular construction delivers clear strategic benefits:

Faster project delivery: Prefabrication and streamlined workflows reduce on-site build time.

Greater accuracy: Integrated simulation and clash detection cut down on errors.

Competitive differentiation: Firms that embrace modular efficiency position themselves as leaders in an evolving construction market.

Scalability: Standardized designs and workflows make it easier to expand operations across multiple sites or projects.

Conclusion

The construction industry is moving toward modularity and efficiency, but success depends on tools that ensure precision, collaboration, and sustainability. CATIA structural engineering empowers teams to design smarter, simulate performance, and streamline modular workflows. By reducing waste, improving coordination, and accelerating delivery, CATIA enables firms to not only meet today’s project demands but also prepare for the future of structural engineering.