Abstract

Aerodynamic performance is no longer a luxury—it’s a necessity in modern automotive design. Whether the goal is to maximize electric vehicle range, reduce fuel consumption, or improve high-speed stability, every curve matters. This article explores how teams are using CATIA for aerodynamics to optimize surface geometry and airflow in vehicle development. From Class A surface refinement to real-time simulation workflows, engineers rely on CATIA to bring efficiency, speed, and accuracy to aerodynamic engineering. The result? Smarter, faster, and more efficient vehicles shaped by digital precision and collaboration.

Why Aerodynamics Defines Modern Automotive Design

In today’s competitive automotive market, aerodynamics is a crucial pillar of vehicle performance. A reduction in drag not only improves top speed and stability but also contributes significantly to energy savings. Whether a vehicle is gas-powered, hybrid, or electric, airflow management is directly tied to overall efficiency and sustainability.

Using CATIA for aerodynamics allows design teams to create sleek body shapes that minimize air resistance while enhancing aesthetics and manufacturability. With the ability to simulate and refine airflow digitally, engineers can start optimizing performance much earlier in the development process.

The increasing emphasis on sustainability and electric mobility further reinforces the need for advanced design tools. Applying CATIA for aerodynamics helps teams ensure that every exterior surface contributes meaningfully to efficiency, from streamlined bumpers to refined rooflines.

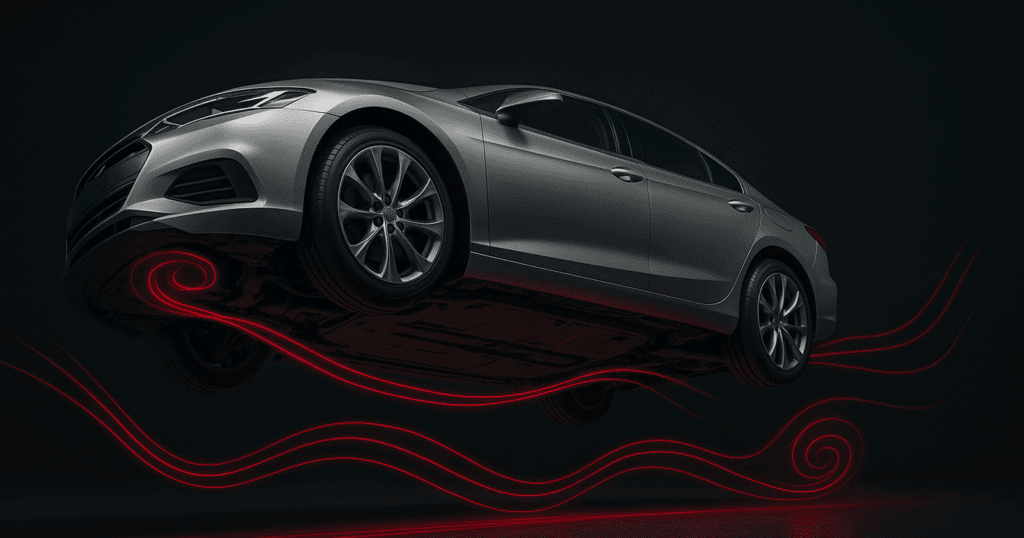

Surface Modeling: The Foundation of Airflow

To create a truly aerodynamic vehicle, engineers need more than visual styling—they need precise, mathematically driven surface control. CATIA offers robust Class A surface modeling tools that empower designers to shape components like fenders, spoilers, hoods, and underbody panels with exceptional accuracy.

When applying CATIA for aerodynamics, teams benefit from:

– High-fidelity curvature control that supports smooth airflow

– Complex geometry creation and manipulation

– Associative relationships between design elements for intelligent updates

– Visual curvature analysis tools to assess surface quality

These features allow engineers to tweak designs based on aerodynamic feedback while maintaining Class A manufacturing standards.

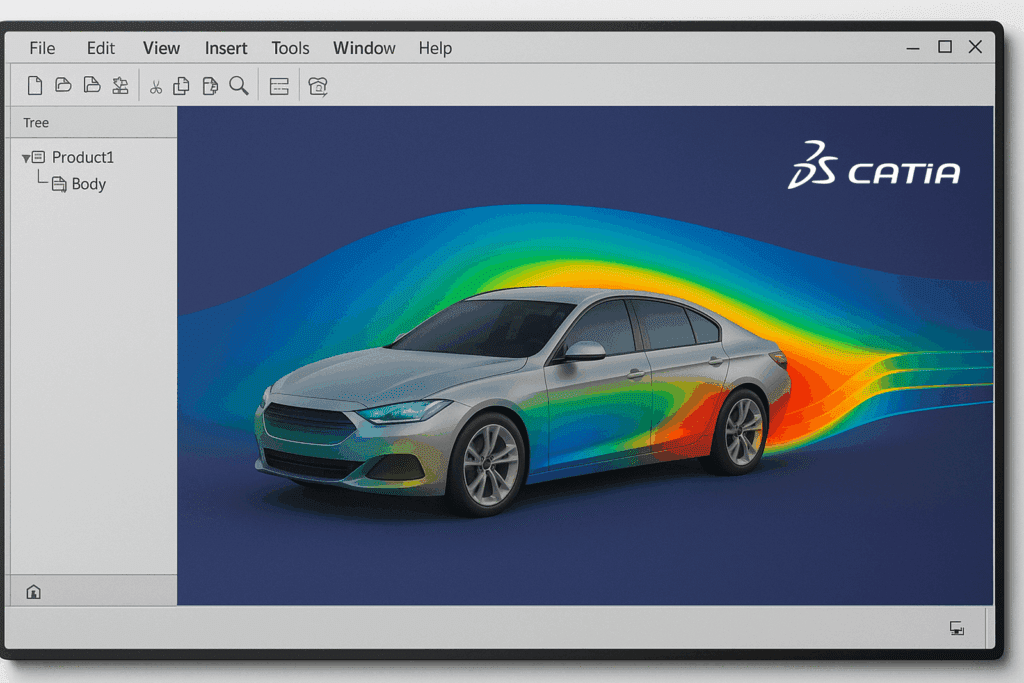

Iterative Design and Real-Time Simulation

Designing for aerodynamics is an iterative process. One change in the roofline or mirror housing can shift airflow dramatically. That’s why combining design and simulation in one environment is so effective.

By leveraging CATIA for aerodynamics, engineers can:

– Simulate airflow digitally using CFD (computational fluid dynamics)

– Evaluate pressure zones and drag forces early in design

– Make real-time design adjustments based on visual flow data

This integrated approach minimizes delays and eliminates the need to recreate models in external platforms. Instead, designers stay focused on innovation, not workarounds.

This design-simulation feedback loop is one of the strongest advantages of using CATIA for aerodynamics. It empowers users to visualize how even minor geometric changes affect overall performance.

A Critical Tool for Electric Vehicle Design

Electric vehicles demand aerodynamic efficiency more than ever. With heavy battery packs and no need for airflow to cool an internal combustion engine, body shapes are evolving quickly. Engineers use CATIA for aerodynamics to experiment with everything from underbody shielding to active airflow systems.

Examples of optimizations include:

– Reducing frontal area to cut drag at highway speeds

– Smoothing underbody geometry to manage turbulent flow

– Integrating diffusers, spoilers, and wheel deflectors

In each case, CATIA for aerodynamics supports both the design creation and the virtual testing needed to validate concepts without producing physical prototypes.

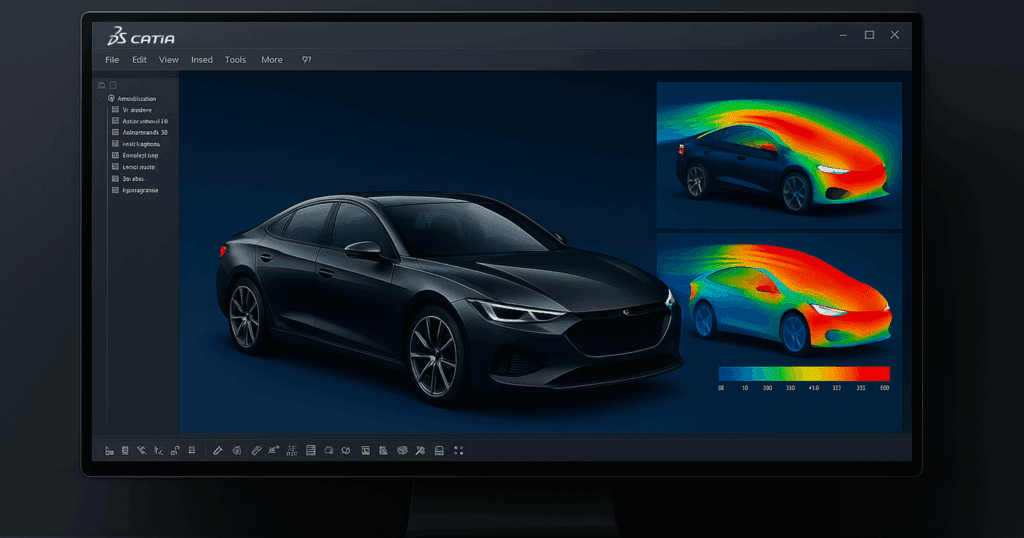

Team Collaboration That Moves Projects Forward

Automotive design is multidisciplinary. Designers, engineers, aerodynamicists, and manufacturing experts all need to contribute without disrupting each other’s workflows. Using CATIA for aerodynamics, teams collaborate in a shared environment where model updates are instantly reflected across departments.

For example:

– Design updates automatically propagate to simulation teams

– Engineering changes maintain surfacing intent and curvature

– Simulation results feed back into design optimization in real time

This model-centric collaboration reduces miscommunication and design drift. Everyone works with a single source of truth—streamlining handoffs and eliminating rework.

Using CATIA for aerodynamics in collaborative environments reduces error rates and accelerates decision-making, especially when teams are geographically distributed.

Simulation-Driven Aerodynamic Decisions

By combining design tools with built-in simulation, CATIA for aerodynamics helps teams make better decisions earlier. Engineers can run virtual wind tunnel tests and generate useful insights like:

– Lift and drag coefficients

– Pressure mapping across vehicle surfaces

– Visualization of turbulent wake zones

– Flow separation detection

This capability ensures vehicles meet aerodynamic goals before reaching physical validation. Instead of correcting issues late in development, designers proactively shape surfaces to guide airflow from day one. With CATIA for aerodynamics, this simulation data isn’t isolated—it’s directly linked to design decisions, creating a seamless path from ideation to implementation.

Flexible for Niche or High-Volume Production

Whether building concept cars, mass-market EVs, or racing prototypes, engineers apply CATIA for aerodynamics to meet specific goals. Small design houses use the same tools as major OEMs to refine spoilers, side skirts, and hoods. Motorsports teams use it to develop splitters and wings that boost downforce.

No matter the size of the project, CATIA for aerodynamics delivers high-precision tools that scale with the complexity and ambition of each vehicle. Whether a team is customizing a racecar or iterating on a mass-produced SUV, the adaptability of CATIA for aerodynamics makes it an invaluable part of the product development cycle.

Aerodynamics and Sustainability

Better aerodynamics doesn’t just improve performance—it directly contributes to sustainability. Reducing air resistance leads to energy savings, especially for EVs. Every improvement in drag translates to extended battery range or improved fuel efficiency.

Using CATIA for aerodynamics, design teams can:

– Reduce reliance on physical prototypes

– Save energy through digital validation

– Develop lighter, more efficient designs

These sustainability benefits are integral to future-focused vehicle development, and CATIA helps deliver them without compromise.

Conclusion: Why CATIA Is the Right Tool for Aerodynamic Engineering

While ‘CATIA for aerodynamics’ is not a formal product title, the phrase reflects a powerful and practical use case. CATIA’s modeling and simulation capabilities make it a premier choice for engineers focused on aerodynamic excellence.

From concept sketches to CFD analysis, CATIA for aerodynamics provides the integrated toolkit required to build sleek, high-performance vehicles that meet both customer expectations and regulatory benchmarks. Teams achieve faster turnaround, reduced costs, and greater design confidence.

Embracing CATIA for aerodynamics ensures your engineering teams are equipped with cutting-edge tools to meet industry demands, optimize energy use, and refine performance—at scale.

Looking to improve your vehicle design process with CATIA for aerodynamics? Mecanica provides expert support and technology solutions to help your team work smarter, faster, and more collaboratively. Get in touch with us today to learn how you can optimize your next project using CATIA for aerodynamic performance. If you’re ready to explore what CATIA for aerodynamics can do for your team, we’re here to help you take the next step.