Abstract

As climate change accelerates and global emissions regulations tighten, manufacturers are being pushed not just to innovate, but to innovate responsibly. From electric vehicles to lightweight materials and modular reuse strategies, the pursuit of eco-conscious engineering is reshaping how cars are designed.

At the center of this transformation is sustainable automotive design—a discipline that blends traditional engineering with advanced digital tools to minimize environmental impact across a vehicle’s entire lifecycle. Using modern CAD and simulation platforms, design teams can evaluate environmental effects at every stage, from raw material sourcing to end-of-life recycling.

This article explores how CAD tools support the core principles of sustainable automotive design and how automakers across industries are leveraging them to build cleaner, greener vehicles for tomorrow.

The Environmental Imperative Driving Change

For decades, vehicle performance was largely defined by horsepower, fuel economy, and aesthetics. But as governments and consumers alike grow more climate-conscious, automakers are being held to new standards. Global emissions targets like the European Green Deal, California’s zero-emission mandates, and net-zero corporate commitments have sparked a race toward environmental accountability.

To remain competitive and compliant, automotive companies must rethink how they approach product development. Sustainable automotive design is no longer a fringe initiative—it’s a strategic imperative.

This shift affects every decision, from material selection and manufacturing processes to component packaging and supply chain logistics. But the scale and complexity of modern vehicle programs demand more than just best intentions—they require sophisticated tools to measure, simulate, and improve sustainability outcomes.

CAD Tools and the New Design Philosophy

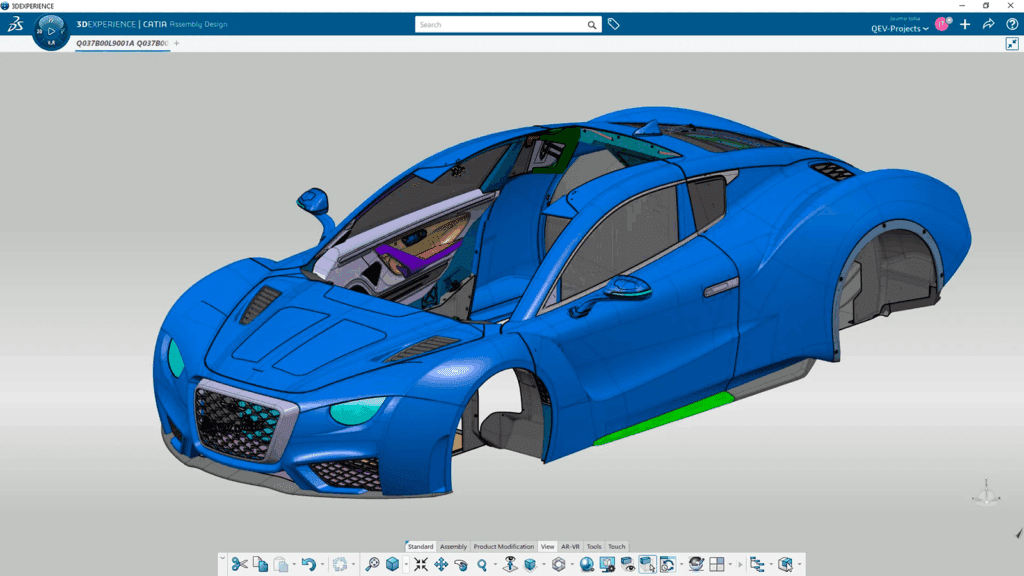

Computer-Aided Design (CAD) has long been central to product development, but its role in sustainable automotive design is rapidly evolving. More than just a tool for geometry, today’s CAD environments integrate sustainability analysis into the very fabric of the design process.

Engineers can now simulate energy use, evaluate environmental impact scores, and visualize product lifecycle footprints within the same software they use to draw parts and assemblies. This integration allows design teams to consider sustainability not as an afterthought, but as a built-in constraint—just like weight or cost.

Designers can test multiple configurations side-by-side, assessing not only performance and manufacturability, but also recyclability, embodied carbon, and energy intensity. These insights empower teams to make environmentally responsible choices from day one. When sustainability insights are part of the design workflow, the entire product development process becomes anchored in sustainable automotive design values.

Lightweighting and Material Efficiency

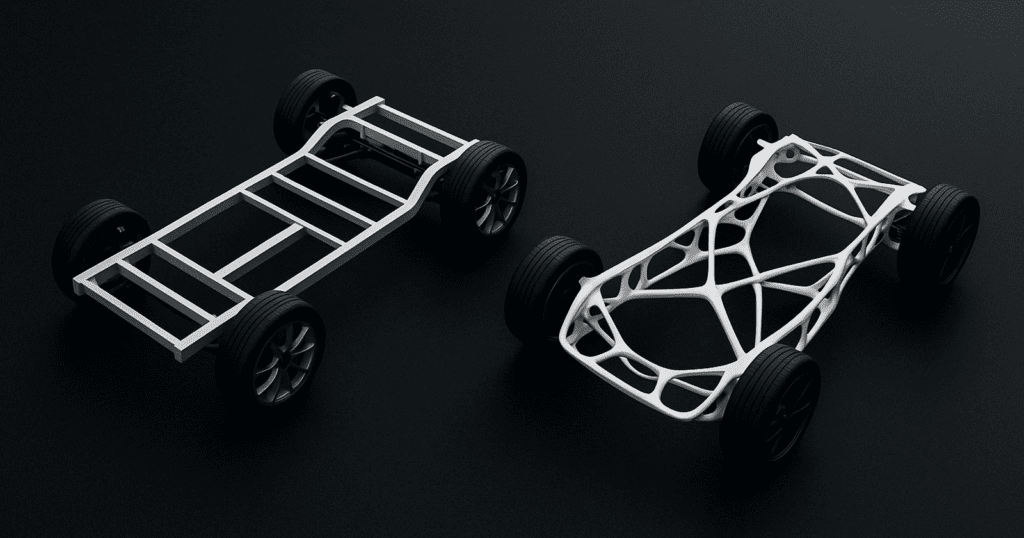

One of the primary drivers of emissions in transportation is vehicle weight. Reducing mass improves fuel economy in combustion engines and extends range in electric vehicles. CAD tools play a critical role in enabling lightweighting strategies that don’t compromise safety or performance.

Within the framework of sustainable automotive design, engineers use CAD to simulate structural loads, impact behavior, and fatigue resistance of lightweight materials such as aluminum, magnesium, and carbon fiber composites. With generative design tools, they can algorithmically explore geometry options that remove unnecessary mass—often creating organic, lattice-like structures optimized for strength-to-weight ratios.

This approach helps designers achieve ambitious weight targets while meeting safety standards, cutting not just operating emissions but also the energy required in production—both of which are essential to sustainable automotive design practices.

Design for Disassembly and Circularity

Another cornerstone of sustainable automotive design is building vehicles that are easier to repair, reuse, and recycle. Traditionally, many automotive components have been overengineered or designed without consideration for end-of-life management. This leads to wasteful disassembly processes and low material recovery rates.

Today’s CAD tools enable engineers to model with circularity in mind. They can flag assemblies that are difficult to separate, assess fastener types, or compare the long-term sustainability of modular versus integrated designs.

Simulation platforms, like the 3DEXPERIENCE platform, can even model the energy and emissions associated with material recovery and remanufacturing, helping designers prioritize not just product durability but overall lifecycle performance. By integrating these insights early, automakers can reduce landfill waste and support emerging circular economy frameworks—key pillars of sustainable automotive design.

Energy Optimization Across the Lifecycle

While tailpipe emissions often grab the spotlight, a large portion of a vehicle’s carbon footprint is locked in during production. Everything from tooling operations to raw material processing consumes energy—and these indirect emissions are increasingly scrutinized in environmental assessments.

Modern CAD and PLM (Product Lifecycle Management) tools now offer sustainability dashboards that visualize a vehicle’s total energy footprint from cradle to grave. Teams can map supplier inputs, calculate embodied carbon, and evaluate tradeoffs between materials or suppliers. These features support sustainable automotive design by uncovering actionable ways to reduce emissions at every stage.

Conclusion: Designing a Greener Future with Digital Tools

Sustainability is no longer optional. It’s a competitive differentiator, a regulatory requirement, and a moral obligation. Sustainable automotive design allows manufacturers to meet all three—and CAD tools make it possible.

From lightweighting and energy modeling to design for disassembly and supply chain visibility, today’s digital engineering environments offer unmatched opportunities to reduce environmental impact at every stage.

The companies that embrace sustainable automotive design and embed it deeply into their workflows will lead the shift toward a cleaner, smarter transportation future. To explore how your teams can integrate sustainable automotive design into your vehicle engineering process, contact Mecanica today for expert insights and implementation support.

Want to explore more about our sustainability solutions? Read through some of our previous articles!