Abstract

Manufacturers are increasingly shifting to cloud-based Product Lifecycle Management (PLM) solutions to streamline production, enhance collaboration, and improve overall efficiency. Traditional on-premises PLM systems, while mostly effective, often lack the flexibility and scalability needed to keep pace with modern distributed supply chains and digital transformation initiatives.

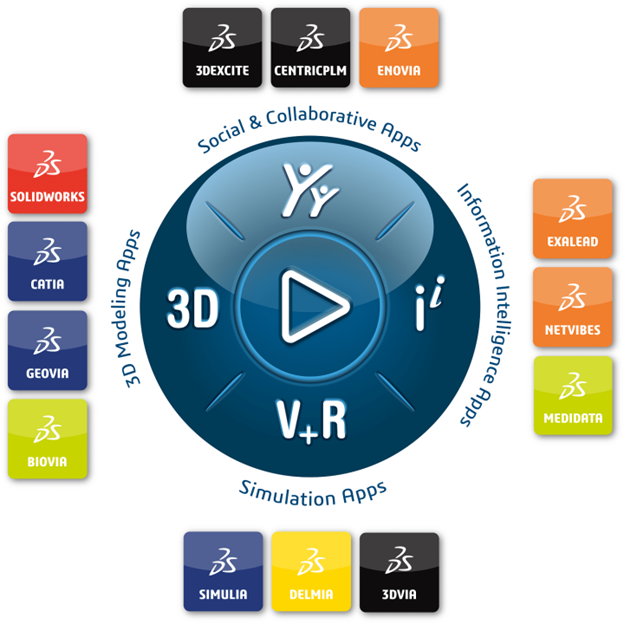

The 3DEXPERIENCE platform offers a fully cloud-based PLM solution, enabling manufacturers to seamlessly connect design, engineering, production, and supply chain management in a single, integrated environment. This article explores how cloud-based PLM for manufacturing is revolutionizing operations, reducing costs, and driving innovation.

Why Cloud-Based PLM is Essential for Modern Manufacturing

Manufacturers operate in an increasingly complex landscape, where shifting market demands, accelerated product cycles, and supply chain disruptions create constant pressure. Traditional PLM systems, reliant on cumbersome IT infrastructure and fragmented data management, often slow innovation rather than enable it. With limited collaboration and manual data transfers, these systems introduce inefficiencies that can hinder agility and competitiveness.

Cloud-based PLM, particularly on the 3DEXPERIENCE platform, eliminates these challenges by providing:

- Real-time collaboration across global teams

- Scalability to meet evolving production demands

- Seamless integration with enterprise systems like ERP and MES

- Lower total cost of ownership (TCO) with reduced IT maintenance

Cloud-based PLM transforms product development by combining the accessibility of the internet with the security of a system built for CAD and product lifecycle management. By eliminating on-premises IT constraints, manufacturers gain the agility to respond to industry shifts, streamline operations, and ensure compliance with evolving regulations—all while maintaining a centralized, collaborative environment.

How PLM for Manufacturing Works on the 3DEXPERIENCE Platform

The 3DEXPERIENCE platform delivers a fully integrated digital manufacturing ecosystem, unifying product design, engineering, simulation, and production workflows within a cloud-based environment. By centralizing these processes, manufacturers can enhance collaboration, optimize production planning, and drive efficiency from concept to execution.

1. Seamless Collaboration from Design to Production

With traditional systems, siloed teams often work in disconnected environments, relying on fragmented data and outdated communication channels. This leads to misalignment between engineering, design, and production teams, costly errors, production delays, and inefficiencies. Oh my!

Without a centralized system, manufacturers struggle to keep track of design revisions, ensure consistency across teams, and coordinate effectively with suppliers. The 3DEXPERIENCE platform eliminates these barriers by enabling:

- Real-time data sharing between engineers, designers, and production teams, ensuring that all stakeholders are working with the most up-to-date information.

- A single source of truth for product revisions, reducing errors caused by outdated documentation or disconnected file systems.

- Supplier and partner integration, streamlining collaboration across the supply chain to prevent bottlenecks and enhance production planning.

By breaking down silos and fostering a fully connected workflow, the 3DEXPERIENCE platform empowers teams to work with greater precision and agility. This seamless connectivity ensures that everyone involved in the manufacturing process—whether in design, engineering, production, or supply chain management—has instant access to the latest product data. The result is faster decision-making, reduced errors, and a more efficient transition from concept to production, giving manufacturers a competitive edge in an increasingly fast-paced industry.

2. Cost Reduction and Operational Efficiency

Traditional PLM systems come with significant financial and operational burdens, requiring substantial investments in software maintenance, IT infrastructure, and periodic system upgrades. Managing on-premises servers, handling security updates, and ensuring system compatibility across teams often lead to high operational costs and reduced flexibility. As industries evolve, these rigid systems can become a bottleneck to growth and innovation.

Cloud-based PLM on the 3DEXPERIENCE platform offers a modern alternative by providing:

- Lower upfront costs, eliminating the need for expensive on-premises servers and dedicated IT support.

- Automatic updates and security patches, ensuring the latest features and compliance standards without IT intervention.

- Flexible, subscription-based pricing, allowing manufacturers to scale resources efficiently based on project demands.

By reducing IT complexity and minimizing maintenance expenses, manufacturers can focus their investments where it matters most—innovation, product development, and optimizing production workflows. The agility of a cloud-based system enables businesses to adapt quickly to market demands, streamline operations, and improve overall efficiency, ultimately driving long-term profitability.

3. Advanced Change and Configuration Management

In fast-paced manufacturing environments, effective change control is critical to maintaining product integrity, regulatory compliance, and production efficiency. Traditional systems often rely on manual processes or disconnected tools, increasing the risk of undocumented changes, version discrepancies, and compliance gaps. These inefficiencies can lead to costly errors, rework, and delays in bringing products to market.

The 3DEXPERIENCE platform addresses these challenges by providing:

- Automated change tracking, ensuring that every design modification is logged, reviewed, and approved in a controlled environment.

- Robust version control, preventing inconsistencies in product designs and ensuring that manufacturing teams always work from the latest specifications.

- Regulatory compliance management, streamlining adherence to industry standards such as ISO, AS9100, and FDA regulations, reducing the risk of non-compliance penalties and ensuring audit readiness.

By centralizing and automating change and configuration management, manufacturers can minimize production errors, reduce material waste, and accelerate the transition from design to manufacturing. This structured approach not only improves product quality and traceability but also enhances collaboration across teams, enabling faster, more informed decision-making throughout the product lifecycle.

4. Scalability and Adaptability for Industry 4.0

As Industry 4.0 accelerates digital transformation, manufacturers must adopt agile, future-ready solutions that seamlessly integrate with IoT, AI, and automation technologies. Traditional PLM systems often lack the flexibility to scale efficiently or support emerging digital manufacturing trends, limiting innovation and responsiveness to market demands.

The 3DEXPERIENCE platform enables manufacturers to embrace the next generation of production with:

- Scalable cloud resources, allowing businesses to expand operations dynamically without the burden of costly infrastructure upgrades.

- Integration with digital twin technology, providing real-time insights into production performance, predictive maintenance, and process optimization.

- AI-driven analytics, enhancing decision-making by optimizing supply chain management, forecasting demand, and identifying potential operational risks before they escalate.

With cloud-based PLM on the 3DEXPERIENCE platform, manufacturers can future-proof their operations, adapt quickly to technological advancements, and maintain a competitive edge in an industry shaped by rapid innovation and automation. By leveraging a connected, intelligent ecosystem, businesses can optimize efficiency, reduce downtime, and drive smarter, data-informed decision-making at every stage of the product lifecycle.

Unlock the Full Potential of Your Manufacturing Operations

Embracing cloud-based PLM is no longer just an option—it’s a strategic necessity for manufacturers aiming to stay ahead in an increasingly competitive landscape. To streamline collaboration, enhance efficiency, and support seamless digital transformation, businesses need solutions that go beyond traditional PLM. The 3DEXPERIENCE platform delivers a fully integrated ecosystem, providing the flexibility, scalability, and intelligence required to optimize product development from design to production.

At Mecanica, we specialize in helping manufacturers implement tailored cloud-based PLM solutions that align with their unique operational needs. Whether you’re looking to enhance collaboration, improve change management, or future-proof your processes, our team is here to guide you.

Dive deeper into Digitalization in Manufacturing in our previous blog post, here.

Ready to take the next step? Contact Mecanica today to explore how cloud-based PLM can drive efficiency and innovation in your manufacturing operations