Located in the heart of the British automotive industry, Vital Auto is an industrial design studio with extensive expertise in automotive design. The company’s impressive client base includes some of the world’s leading car manufacturers, such as Volvo, Nissan, Lotus, McLaren, Geely, TATA and more.

“Customers typically come to us to try to push the boundaries of what is possible with available technology,” said Shay Moradi, vice president of innovation and experimental technology at Vital. When manufacturers don’t have time to experiment themselves, they turn to Vital Auto to turn ideas, initial sketches, drawings or technical specifications into a well-developed physical product.

Read on to learn how Vital Auto quickly creates and iterates high-fidelity prototypes and concept cars using a variety of advanced tools such as its Form 3L and Fuse 1 printer fleet.

The creation of a concept car

Vital Auto was founded in 2015, when three friends decided to get together, quit their jobs, and open a store in a garage (of course). One of the first contracts the company landed was for the NIO EP9 supercar concept, which immediately got the team interested in producing extremely realistic, high-fidelity vehicle prototypes.

Depending on the customer’s request, the team may base their designs on a simple sketch drawn on a piece of paper or on a previously designed vehicle. They develop the cars from start to finish, designing the chassis, exterior and interior elements, hinges and interactive elements. With five to 30 employees working on a single concept, a project can often take three to twelve months.

During that time, a show car may go through as many as a dozen basic concept iterations, which may themselves include iterations of smaller components, until the design meets the customer’s expectations.

“It’s quite normal in our industry to consider the virtual properties of a product to evaluate it before it goes to market. But I think there will always be a place for physical manufactured objects. There’s nothing better than holding an object that is the right weight and proportion and being able to look at it from different angles,” Moradi said.

“Most of our customers come to us with a new idea; something innovative that has never been done before. So there are new challenges every day, and they keep coming up,” said Anthony Barnicott, design engineer in charge of additive manufacturing. “These challenges are diverse and varied: we may be looking at how to produce a certain number of parts in a given time, how to make a durable product, or how to make a part that can achieve a particular weight and still give a particular performance.”

Traditional show cars are typically made by machining clay, and the team also uses three- and five-axis CNC milling, hand forming, hand shaping of clay and glass-reinforced plastic composites. However, these traditional processes are often not ideal for producing the custom parts required for unique designs.

“We have been using 3D printing since day one. We wanted to incorporate it into our manufacturing processes, not only to reduce costs, but to give customers more diversity in their designs and ideas,” Barnicott said.

Today, Barnicott leads a 3D printing department that includes 10 large-format FDM printers, three large-format Form 3L SLA printers and five Fuse 1 SLS printers.

“In terms of capacity, all of these printers have been running at 100 percent, 24/7, pretty much from day one. We use these printers for all kinds of concepts and designs. Generally, we use the Fuse 1s for our production parts and the Form 3Ls for our concept parts,” Barnicott says.

Complex designs made possible by the different materials of the Form 3L

“We use Form 3L machines for all Class A surfaces. These are usually automotive or interior environments, where there are areas that are not covered with leather, alcantara or other types of fabric. Formlabs materials have a nice smooth finish, and they can be painted easily. We can use these parts right out of the printer, and put them directly on a vehicle,” Barnicott said.

“The thing that interests me most about the Form 3L is its versatility: we can choose from its wide range of materials and change resins in less than five minutes. We can go from soft and flexible to hard and rigid, which for us is an invaluable advantage,” Barnicott said.

The team uses Form 3L with several materials for a wide range of applications, for example:

Air vents

“It’s a challenge we often face: customers look to us to incorporate a proprietary product into their own design. One customer showed us a proprietary air vent from another vehicle that he wanted to have in his own interior. We used 3D scanning technology to get a virtual copy of the part and then lined it with an outer wall. We first printed it with Draft Resin to test the design and allow the client to review it. We then switched to White Resin to produce a production-ready part.”

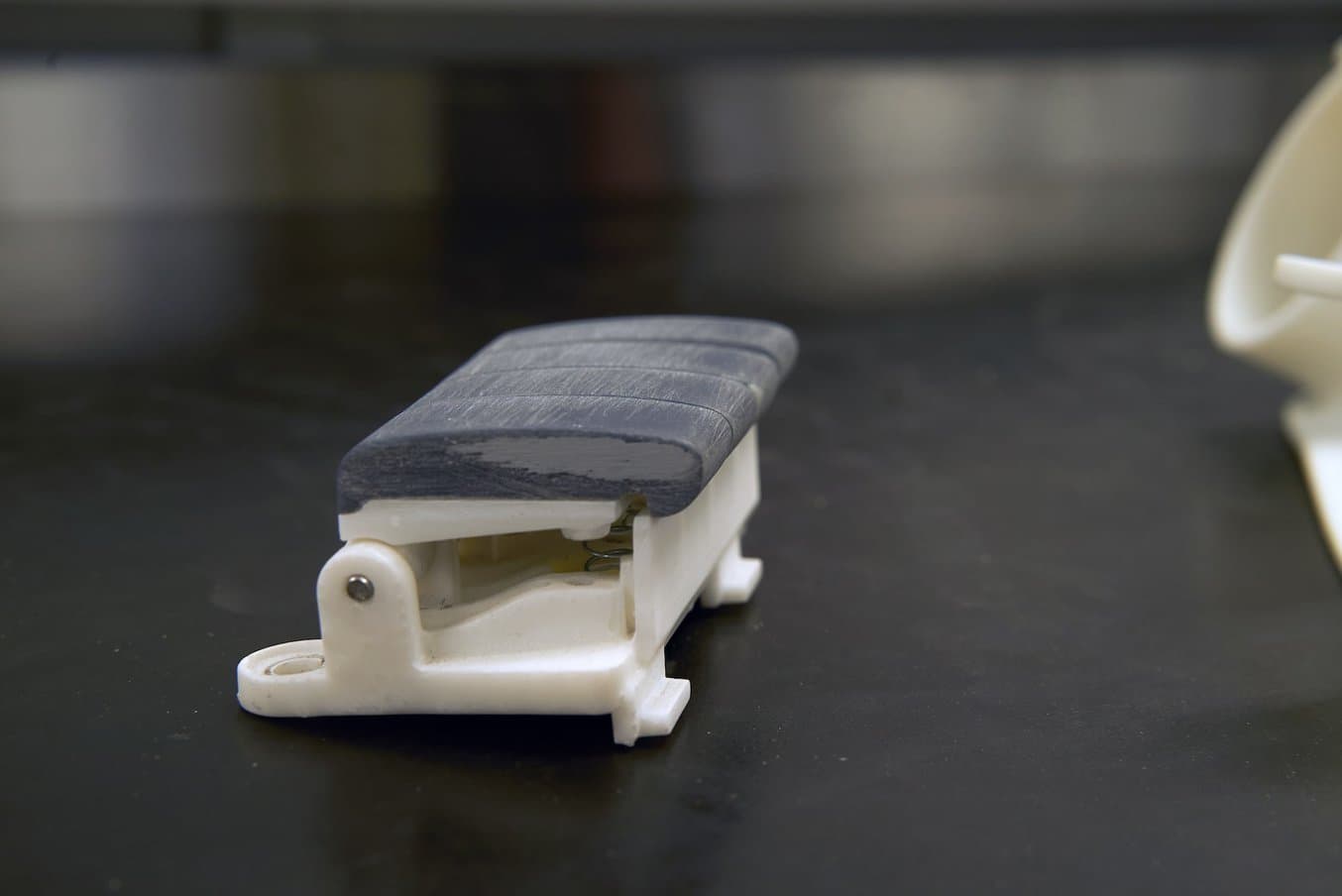

Switchboxes

“When we work on very complex designs such as small switchboxes, we are able to use multiple materials to achieve a mechanical product that not only works properly, but can also be used in a real-world environment. [For these switchboxes], we combined harder materials, such as Tough 2000 for the top surface, with lighter, more cost-effective materials for the internal components.”

Door seals

“In general, door seals are incredibly expensive to produce. The only way to do this is to use extrusion molding. This not only results in very high tooling costs, but also long lead times. We were able to experiment with one of Formlabs newest materials: Flexible 80A Resin. The Form 3L allowed us to produce sections of this door seal overnight to test different geometries. It ended up being printed with a difference of only 50 microns from the original design.

Having the Form 3L allows the team to produce multiple iterations of parts, usually in less than 24 hours. In the end, they decided to purchase three machines to produce up to three part iterations at the same time, using three different materials. The savings allow them to present the customer with multiple design options for the same price.

“One of the benefits of additive manufacturing is time compression. So what do we do with this freed-up time? We see it as expanding the realm of possibilities that allows us to imagine alternative solutions, and add more iteration to the process,” Moradi said.

“Many of our products simply could not be manufactured without our 3L Forms. With some advanced manufacturing techniques like seven-axis CNC machining, we would be able to produce these parts, but at a very high cost,” Barnicott said.

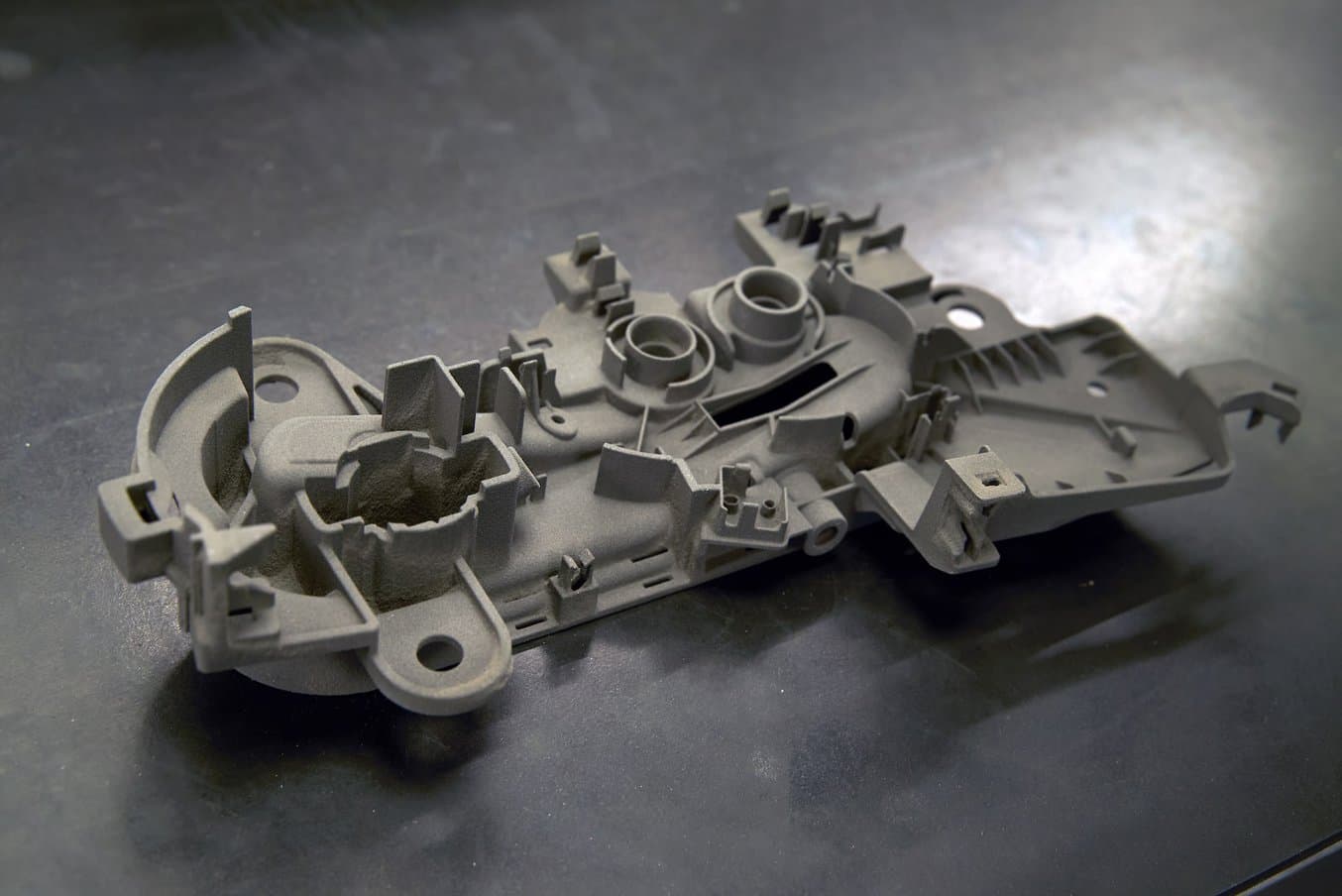

Complete CNC machining of mechanical parts with the Fuse 1

“The Fuse 1 was our first experience with SLS technology. Being a small company, it’s a technology we never thought we would have access to at our site. We have five Fuse 1s. These machines have allowed us to produce structural mechanical parts to test not only physical applications in record time, but also most of our designs. Previously, we outsourced or machined them in-house depending on their geometry, and we usually had to wait two to four days to get the parts in our hands. The Fuse 1 allows us to produce all of this in-house and have the parts in hand in less than 24 hours,” said Barnicott.

The team primarily uses Fuse 1s for mechanical parts such as hinges, handles, and internal door components, as well as for structural applications. The parts are ready to use right out of the printer, and require minimal finishing. Examples of Fuse 1 applications include:

Ventilation duct

“Many automotive interior parts can be incredibly difficult to produce without injection molding. Air ducts and internal vents are items that you never see, yet are very expensive to produce. We use the Fuse 1 to produce these parts. This allows us to be much more versatile with our vehicle designs without breaking the bank.”

Brake caliper

“Sometimes we produce parts just so customers can see what their brand will look like on them. That means we need to produce a part fast enough to put their logo on it. We use the Fuse 1 to produce these types of parts, such as a brake caliper, and we can place the logo on different areas of the caliper using multiple colors for the customer to decide.”

Interactive concept for a super car

“3D printing has allowed us to combine SLA and SLS materials to work on conceptual iterations within a specific project. By combining the two processes and taking advantage of their specific properties, we can quickly produce multiple iterations to arrive at a final design. This can range from mechanical parts to transparent parts, which we can verify for optical quality and performance.”

While it’s often said that additive manufacturing is here to replace subtractive manufacturing, the team at Vital Auto sees benefits in combining these technologies to enhance their qualities.

“We combine the two to make the best use of them. We have many parts where we use subtractive manufacturing and then additive manufacturing to make the details finer. This gives us a cost-effective way to produce a large number of conceptual models,” Barnicott said.

Creating high fidelity concept cars with 3D printing

“The progress 3D printing has made in the last ten years is phenomenal. I started out producing niche vehicles in small batches, but when I see our current capabilities, I realize that some of the parts we make today would have been absolutely unattainable back then,” Barnicott said.

3D printing not only helps the team create better products faster, but also helps them attract new customers. They’ve found that many of their customers come to them because they want access to the latest technologies and want their components made with state-of-the-art materials.

“Some technologies that were considered emerging are now beyond that. 3D printing is one example. It has reached such a point of perfection that everything we produce can be used directly for the final product, after all our modifications have been applied. 3D printing was a novelty at first, but today it is an integral part of what we do,” said Moradi.