Abstract

Digital platforms like the 3DEXPERIENCE have evolved beyond simple online tools—they’re now becoming intelligent collaborators that actively enhance our design processes. Imagine a workspace where repetitive tasks vanish, insightful recommendations appear proactively, and every engineer is free to fully unleash their creativity. Welcome to the reality powered by AI-driven automation within CAD design.

In this article, we explore how the 3DEXPERIENCE platform is leading the charge in AI integration, embedding artificial intelligence to accelerate workflows, drive innovation, and enhance product quality—turning concepts into outstanding products faster and more efficiently.

The Evolution of CAD Design: From Manual to Intelligent

Computer-Aided Design (CAD) has evolved dramatically since its early days. Initially, CAD software digitized manual drafting processes on massive workstations that filled whole rooms. But this technological step forward provided much-needed faster drawing capabilities without fundamentally altering the design process.

Over time, our computers have gotten smaller and more powerful, and upgrades like feature-based modeling, parametric control, and integrated simulation have transformed CAD into the powerhouse of digital engineering we know and love, but the fundamental design process has remained largely unchanged.

Today, the next frontier is intelligence: empowering CAD systems to actively participate in design workflows. With the introduction of AI in CAD design, platforms like 3DEXPERIENCE are no longer just passive drawing boards—they’re proactive collaborators. Intelligent algorithms anticipate user intent, suggest optimizations, detect errors early, and automate repetitive modeling tasks that once consumed valuable engineering hours.

This shift enables designers and engineers to spend less time on mechanical work and more time on creativity, analysis, and innovation.

How 3DEXPERIENCE Integrates AI into CAD Workflows

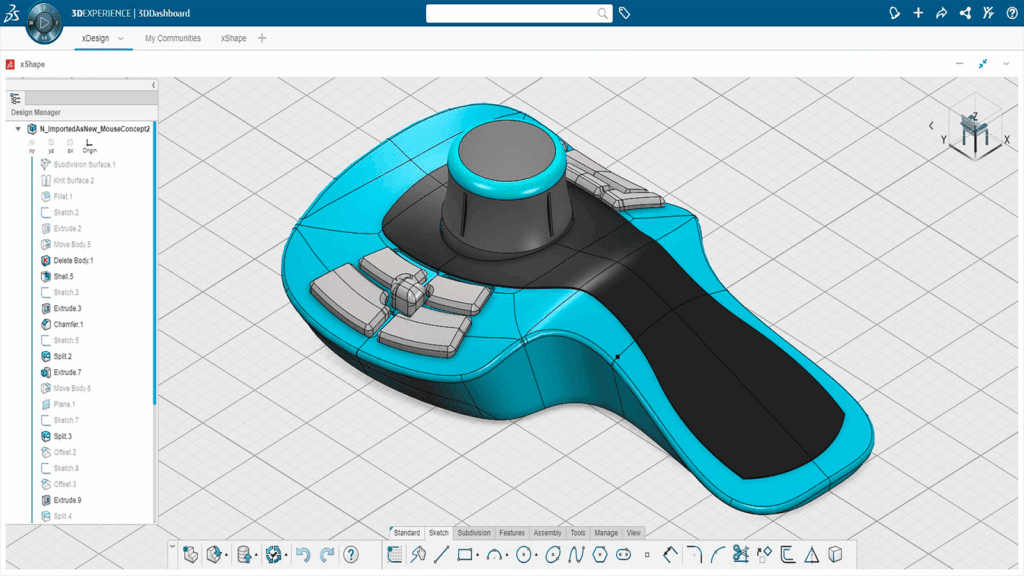

Dassault Systèmes’ 3DEXPERIENCE platform illustrates how AI can be seamlessly integrated into the design workflow, enhancing efficiency without compromising creativity or engineer oversight. Let’s explore how it accomplishes this in a bit more detail.

Predictive Modeling and Feature Recognition

Through machine learning, 3DEXPERIENCE learns common workflows and suggests features, alignments, or constraints based on past user behaviors and similar design patterns. Instead of manually defining every fillet, hole, or fastening detail, engineers receive real-time predictive recommendations that accelerate modeling.

Automated Design Validation and Error Detection

AI-driven validation engines actively scan models for geometric inconsistencies, assembly interferences, and compliance issues. Rather than waiting for a manual review, the platform flags potential problems as they arise. This real-time feedback loop reduces downstream errors and costly manufacturing rework.

Generative Design Optimization

One of the most revolutionary applications of AI in CAD design is generative design. Here, engineers input functional goals, material preferences, and manufacturing constraints—and the AI proposes innovative, often unexpected, geometry solutions. 3DEXPERIENCE enables users to rapidly explore hundreds of optimized variations, resulting in structures that are lighter, stronger, and more sustainable.

Check out our previous article that goes into more detail about AI-driven sustainable design.

Task Automation and Intelligent Assistants

Routine operations like part documentation, bill of materials generation, fillet application, and drawing updates can be automated with intelligent assistants. Instead of manually reapplying standard features across assemblies, engineers delegate these tasks to AI workflows that ensure consistency and save time.

Enhanced Collaboration through Data Insights

AI doesn’t just improve design modeling—it enhances cross-functional collaboration. In the 3DEXPERIENCE environment, AI monitors project activities, flags task dependencies, and suggests next steps for distributed teams. This application of AI in CAD supports faster, clearer decision-making across mechanical, electrical, and manufacturing domains.

Specific Features for AI in CAD Design

One of the key features introducing AI-driven design on the 3DEXPERIENCE platform is the Project Planner role, which facilitates comprehensive project management. It allows teams to define project objectives, create task dependencies, assign resources, track progress, and generate reports. This tool is particularly effective for managing complex projects, such as product development, by streamlining workflows and improving team productivity.

Additionally, the platform’s Collaborative Industry Innovator role enables real-time concurrent design, allowing designers to work in parallel and have instant access to updates made by other contributors. This feature enhances decision-making and accelerates design maturity by ensuring that all team members are working with the most current data.

The Benefits of AI-Driven Automation in 3DEXPERIENCE

The real power of AI lies not only in speed but also in the quality of outcomes. Integrating AI in CAD design through 3DEXPERIENCE offers transformative benefits:

- Accelerated Product Development: By automating repetitive tasks and optimizing design alternatives, engineering teams can dramatically shorten time-to-market.

- Reduced Risk of Errors: Early validation and predictive checking minimize manufacturing errors and quality failures.

- Expanded Design Exploration: Generative capabilities let teams explore broader solution spaces and identify breakthrough designs that may be missed through traditional methods.

- Talent Optimization: Engineers focus their energy on solving complex, value-added challenges rather than repetitive operations.

- Higher Project Transparency: AI insights ensure better project tracking, task prioritization, and team coordination across all stages of development.

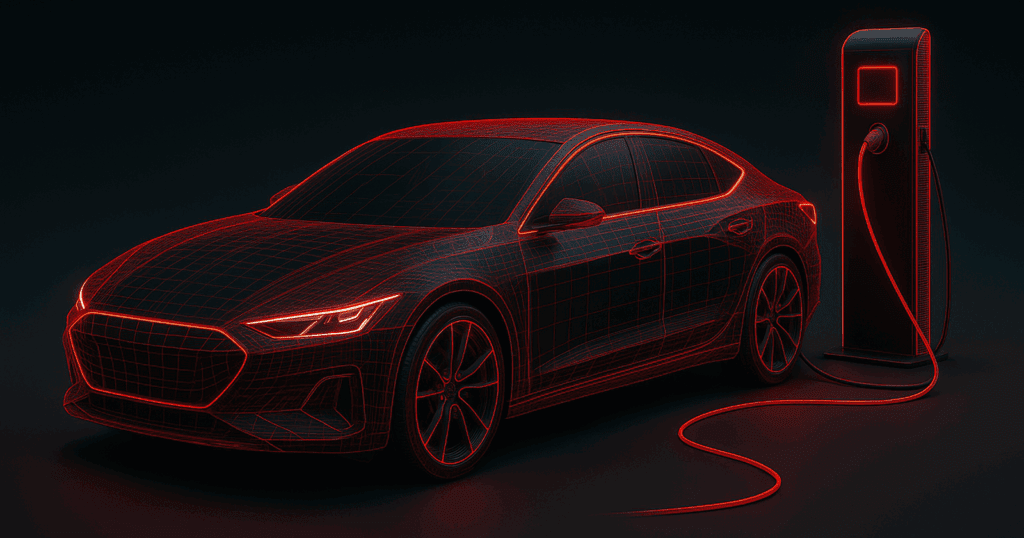

Real-World Applications of AI in CAD Design

- Aerospace and Defense: AI-generated lightweight structures reduce aircraft weight while maintaining performance under stress and thermal loads.

- Automotive: Automated assembly validation in 3DEXPERIENCE reduces time spent correcting tolerance stack-ups and improves manufacturability of electric vehicle platforms.

- Consumer Electronics: Generative AI enables compact design layouts that maximize functionality within smaller form factors.

- Industrial Equipment: Predictive modeling streamlines machine part standardization and reusability across product lines.

In each case, 3DEXPERIENCE’s use of AI accelerates innovation while maintaining strict quality, safety, and sustainability standards.

Implementing AI in CAD: Solutions for Success

Integrating AI into your CAD processes opens the door to incredible opportunities, transforming how your design teams innovate and collaborate. While the journey to successful adoption takes careful planning, the rewards are well worth the effort. By proactively preparing your teams, establishing clear strategies, and fine-tuning workflows, you can smoothly navigate common implementation hurdles. Start strong by prioritizing comprehensive onboarding, rigorous validation, high-quality data management, and a culture that celebrates innovation. This approach will empower your organization to truly harness the full potential of AI-driven design.

Empower Designers through Training: Equip design teams with targeted training programs, enabling them to effectively interpret, validate, and confidently integrate AI-driven recommendations into their workflows.

Adopt Rigorous Validation Protocols: Establish clear processes for simulation-based validation and testing of AI-generated designs, ensuring accuracy, quality, and reliability in every project.

Prioritize Data Quality Management: Implement robust data governance practices, ensuring that AI algorithms continuously learn from accurate, relevant, and well-structured datasets to improve model precision and applicability.

Cultivate Collaborative Innovation: Promote a culture where AI is positioned as a creative partner, enhancing human expertise rather than replacing it, thus encouraging designers to actively explore innovative ideas with AI support.

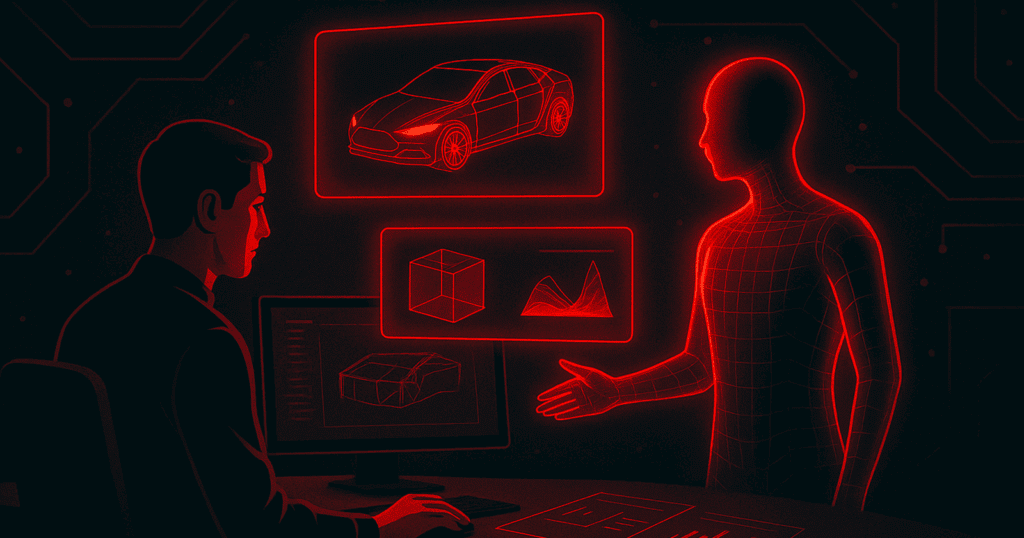

The Future of AI in CAD Design: From Co-Pilot to Partner

Looking ahead, AI in CAD design will continue to mature from automation tool to creative partner. Future systems promise to not only suggest optimizations but actively collaborate during the design ideation phase, proposing innovative solutions in real time based on changing requirements and contextual intelligence.

Imagine CAD environments where AI can propose complete assemblies based on functional needs, conduct early-stage performance simulations, suggest sustainable material alternatives, and even predict manufacturing bottlenecks! The 3dexperience platform is steadily advancing toward this future, continuously expanding its suite of intelligent design assistants and predictive engines.

Conclusion: Empowering Designers with AI in 3DEXPERIENCE

AI is transforming CAD design, making collaboration smoother and innovation easier than ever. With tools like the 3DEXPERIENCE platform, engineers can skip repetitive tasks and break free from traditional workflow limitations.

Instead, your team can use AI to boost creativity, fine-tune product performance, and speed up the design process—without sacrificing quality or originality.

Want to keep your team in the loop on the latest in AI-driven CAD innovation? Follow Mecanica—find us on LinkedIn, Facebook, or sign up for our newsletter—we’re here to help you get the most out of your 3D product development tools.