Overview

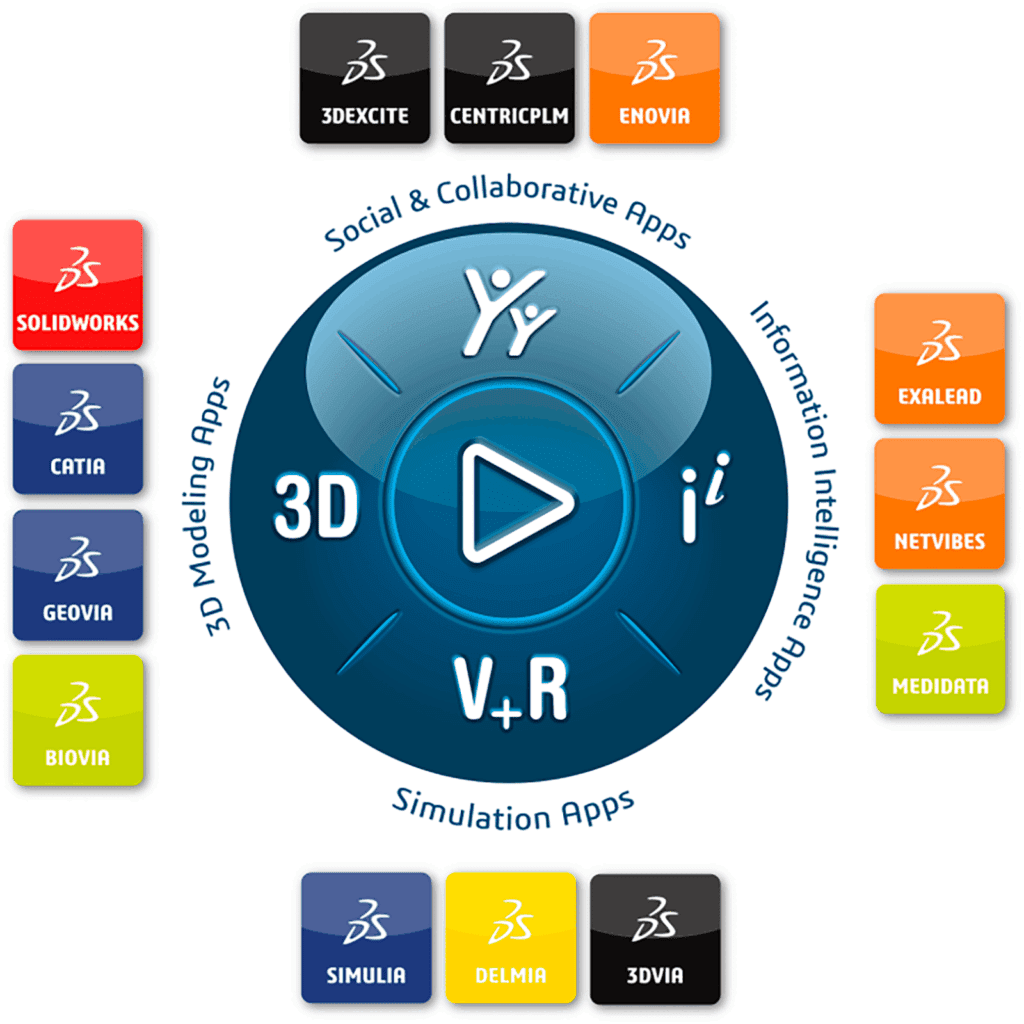

Efficient resource management is essential for industrial equipment manufacturers striving to maintain competitive advantages, control costs, and maximize productivity. This blog explores how Dassault Systèmes’ 3DEXPERIENCE platform specifically tackles resource management challenges, enabling manufacturers to optimize operations and significantly enhance their bottom line.

The Importance of Efficient Resource Management

Resource management lies at the heart of successful industrial equipment manufacturing. Companies that can effectively track, allocate, and optimize resources, ranging from raw materials and components to human labor and machinery, gain substantial cost savings, improved product quality, and streamlined operations. The 3DEXPERIENCE platform’s advanced PLM capabilities directly address these crucial aspects, offering a structured, integrated solution.

Common Pitfalls in Resource Management

Many industrial equipment manufacturers grapple with persistent challenges in resource management. Poor demand forecasting can lead to overstock or shortages, while production bottlenecks often stem from misaligned workforce allocation. Inaccurate or outdated data can derail procurement decisions, and a lack of visibility into supply chain disruptions leaves teams scrambling to adapt. Redundant manual tasks further slow down operations, compounding these issues and directly impacting profitability, lead times, and customer satisfaction. Addressing them requires robust, data-driven solutions.

Centralized Visibility and Control with ENOVIA

Additionally, ENOVIA allows manufacturers to standardize processes globally, ensuring consistent data governance across multiple plants or business units. This harmonization improves responsiveness to supply chain disruptions and reduces the risk of costly errors. ENOVIA also integrates with quality management systems, ensuring that resource-related decisions align with product standards and compliance.

Predictive Analytics and Smart Planning with NETVIBES

NETVIBES transforms reactive management into proactive, strategic decision-making. For instance, if a key supplier faces a sudden material shortage, NETVIBES can alert teams early and suggest alternative sourcing options based on historical supplier performance and market availability. It also allows users to track geopolitical risks, weather patterns, and economic trends that may affect supply chains, providing comprehensive situational awareness that improves decision-making at every level.

Streamlined Workflow Automation with DELMIA

This ability to model multiple production scenarios allows companies to optimize plant layouts, reduce machine downtime, and improve labor utilization. It means teams can adapt quickly to custom orders, rush jobs, or last-minute design changes. DELMIA also supports workforce planning, ensuring that the right personnel are assigned to the right tasks with consideration for skills, certifications, and shift availability.

Real-Time Collaboration via 3DSwym and ENOVIA Collaborative Innovation

Miscommunication is a common cause of resource inefficiencies. 3DSwym and ENOVIA Collaborative Innovation foster transparency and collaboration by providing shared digital workspaces. These platforms offer real-time updates on project status, resource allocations, and task completions, while also supporting discussion boards, wikis, and live feeds that significantly reduce the reliance on lengthy email chains and repetitive meetings.

By enabling engineering, procurement, and operations teams to share updates and solve issues in real-time, 3DSwym prevents delays caused by information gaps and accelerates decision-making. These tools also facilitate collaboration with external stakeholders, including suppliers and contractors, ensuring everyone is aligned and informed throughout the product lifecycle.

Integration with ERP and Supply Chain Systems

The 3DEXPERIENCE platform complements existing ERP and supply chain management systems seamlessly. Through APIs and integration tools, manufacturers can synchronize real-time resource and inventory data between systems, bridging the gap between engineering (PLM) and operations (ERP). This allows for procurement triggers to be automated based on design changes or production needs and maintains end-to-end traceability across the supply chain.

This level of integration ensures that any updates in product design immediately reflect in procurement and production planning, preventing costly mistakes like ordering incorrect parts or producing obsolete components. It also supports financial forecasting by providing accurate resource consumption data, contributing to smarter budgeting and more effective cost management.

Enhancing Sustainability with Sustainable Innovation Intelligence

Sustainable Innovation Intelligence within the platform empowers companies to evaluate the environmental impact of materials and processes. This tool allows teams to optimize designs for lower material waste and energy consumption while implementing circular economy strategies such as remanufacturing and recycling. It also ensures compliance with increasingly strict environmental regulations.

Beyond compliance, it enables companies to set ambitious sustainability benchmarks and monitor their progress toward carbon reduction goals. Manufacturers can simulate the impact of different materials or process changes on sustainability metrics, helping teams make environmentally conscious decisions without compromising performance or profitability.

Real-World Impact: Resource Management in Action

Imagine a manufacturer struggling with fluctuating material costs, supplier delays, and excessive downtime due to equipment failures. By implementing the 3DEXPERIENCE platform, the company gains access to ENOVIA for real-time inventory and material tracking, NETVIBES for supply chain risk predictions, and DELMIA for automated production scheduling that dynamically reallocates labor and resources as needed. Teams stay aligned thanks to 3DSwym’s real-time communication tools, and sustainability tools actively measure the carbon footprint of various production scenarios.

Beyond reducing operational costs and improving delivery timelines, the company also achieves higher customer satisfaction thanks to reliable lead times and a measurable reduction in waste and emissions. Teams experience fewer production stoppages, better supplier relationships, and a noticeable boost in operational agility.

The ROI of PLM for Resource Management

Adopting PLM within the 3DEXPERIENCE platform delivers measurable ROI. Companies report reductions in material waste of up to 30%, significant decreases in inventory holding costs, and improved equipment uptime through predictive maintenance. Automated workflows accelerate time-to-market while reliable delivery timelines improve customer satisfaction.

These financial benefits are just the beginning. Organizations also gain resilience in the face of supply chain disruptions, reduced environmental liabilities, improved regulatory compliance, and a stronger brand reputation. Over time, this positions manufacturers for greater customer retention, smoother entry into new markets, and sustained operational excellence.

Conclusion: Achieving Operational Excellence

For industrial equipment manufacturers, efficient resource management isn’t just beneficial, it is vital. The 3DEXPERIENCE platform uniquely addresses this challenge with tools like ENOVIA, DELMIA, NETVIBES, 3DSwym, and Sustainable Innovation Intelligence. These solutions optimize resource usage, streamline processes, enable data-driven decision-making, enhance collaboration, and embed sustainability into daily operations.

By adopting this integrated platform, manufacturers can transform their resource management practices, boosting profitability, operational resilience, and competitiveness in an increasingly dynamic industry.

Ready to optimize your resource management? Contact our specialists today to explore how the 3DEXPERIENCE platform can revolutionize your operations.