Overview

Artificial intelligence (AI) is significantly transforming automotive manufacturing. Smart factories powered by AI technologies enhance production efficiency, reduce operational costs, and improve product quality.

This article explores specific AI-driven solutions, including predictive maintenance, generative design, and supply chain optimization, highlighting how AI in automotive manufacturing is reshaping industry practices with concrete examples and practical insights.

The Role of AI in Automotive Manufacturing

The automotive industry has historically relied on precision, consistency, and large-scale production efficiencies. However, modern consumer demands are shifting rapidly, requiring faster innovation cycles, greater customization, and adherence to stringent sustainability targets. Smart factories powered by AI provide the necessary agility, delivering real-time analytics, decision-making capabilities, and proactive problem-solving methods essential for maintaining competitiveness in automotive manufacturing.

Practical Applications of AI in Automotive Manufacturing

Predictive Maintenance

Predictive maintenance harnesses machine learning algorithms to analyze data collected by sensors embedded in manufacturing equipment. By using AI in automotive manufacturing, companies such as BMW effectively predict mechanical faults, allowing timely maintenance that significantly reduces downtime and avoids costly disruptions. BMW’s smart maintenance system continuously monitors equipment conditions, effectively forecasting and mitigating production interruptions.

Process Optimization and Enhanced Quality Control

Quality control is a critical element in automotive manufacturing, ensuring product reliability and safety. AI-powered visual inspection systems offer rapid and precise detection of defects such as misalignments or paint inconsistencies. Audi, for example, uses sophisticated AI-driven inspection systems throughout its manufacturing process, identifying potential quality issues quickly and accurately, which significantly reduces waste and improves overall product quality.

“Today, we assume that digitalization can reduce factory costs by up to 30 percent overall. AI will be a decisive part of that.”

AI Expert, Rüdiger Eck

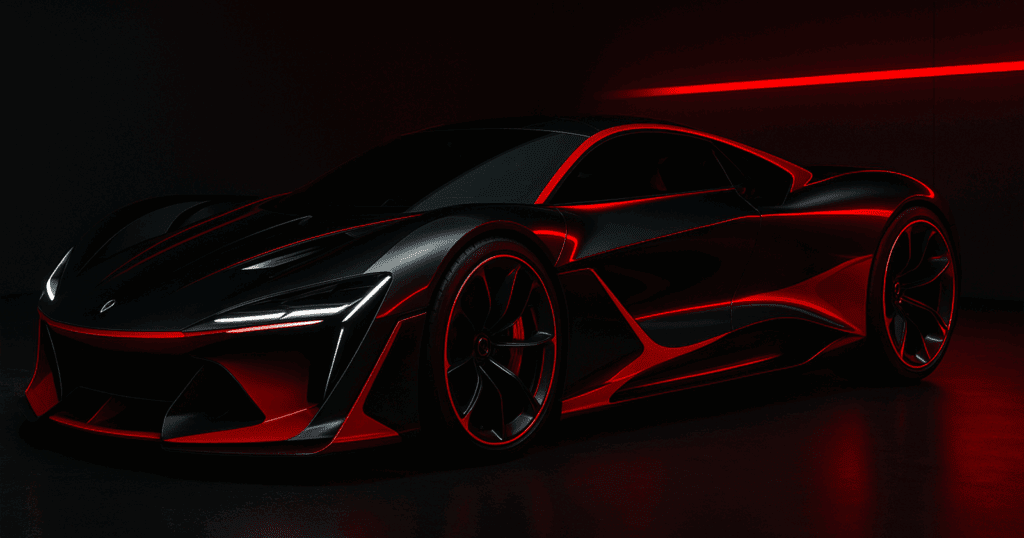

Generative Design

Generative design employs AI algorithms to create optimized automotive components by evaluating multiple design options based on defined constraints like weight, strength, and material properties. Utilizing generative design within AI in automotive manufacturing allows engineers to significantly enhance performance characteristics, resulting in lighter and more efficient components. This method supports the industry’s growing emphasis on sustainability and energy efficiency.

To dive deeper, check out our previous articles on Generative Design!

👉 The Future of Sustainable Design with Generative Algorithms

👉 CATIA Generative Design: Exploring Lightweight Structures

👉 AI-Driven Generative Design for Lightweight Vehicles

Supply Chain Optimization

AI algorithms manage intricate automotive supply chain networks, predicting disruptions, optimizing logistics, and automating inventory control processes. By applying AI in automotive manufacturing supply chains, manufacturers can swiftly respond to market fluctuations, material shortages, and delivery delays. Enhanced analytics enable better decision-making, reduce inventory costs, and maintain consistent production throughput, ensuring supply chains are resilient and adaptable.

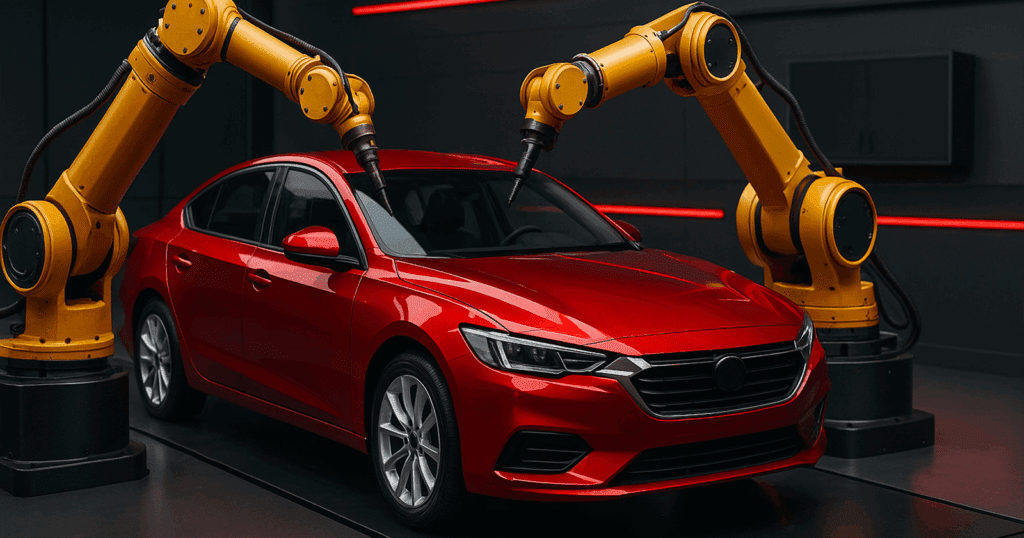

Autonomous and Flexible Production Systems

Autonomous robotics and adaptive scheduling represent another crucial area where AI significantly benefits automotive manufacturing. AI-enhanced automation can dynamically adjust production schedules and robot operations in response to real-time demand and production variances. This flexible production capability allows manufacturers to quickly scale production capacities, respond to consumer preferences, and handle complex customization demands efficiently.

Tangible Benefits of AI Integration

- Reduced Production Time: AI-driven processes and predictive analytics expedite product development and reduce time-to-market significantly.

- Cost Efficiency: Predictive maintenance, quality control improvements, and optimized material usage dramatically reduce overall production and operational expenses.

- Enhanced Sustainability: AI-driven precision minimizes waste, lowers energy consumption, and supports environmentally responsible manufacturing processes.

- Improved Product Quality: Advanced inspection techniques and consistent process optimization significantly enhance the final product’s reliability and durability.

Future Directions: The Expanding Role of AI in Automotive Manufacturing

As the automotive industry shifts towards electrification, automation, and enhanced connectivity, the role of AI in automotive manufacturing will continue to expand exponentially. Next-generation smart factories will deeply integrate AI across their entire operational spectrum, from design and prototyping to full-scale production and after-sales support. Future facilities will increasingly utilize fully automated “lights-out” operations, further refining precision manufacturing capabilities, enabling greater product personalization, and upholding higher safety and compliance standards.

Leveraging the 3DEXPERIENCE Platform in Automotive Manufacturing

The 3DEXPERIENCE platform by Dassault Systèmes enhances AI-driven smart manufacturing capabilities by providing a unified environment for collaboration, simulation, and product lifecycle management (PLM). Integrating AI tools with the 3DEXPERIENCE platform enables automotive manufacturers to create comprehensive digital twins of manufacturing processes, thereby optimizing efficiency and reducing physical prototyping needs.

Enhanced Collaboration and Communication

Through integrated tools like 3DSWYM and ENOVIA, teams across the globe can collaborate seamlessly on product designs, process enhancements, and quality improvements. The platform ensures that all stakeholders have real-time access to accurate and updated information, facilitating better decision-making and streamlined operations.

Advanced Simulation Capabilities

Simulation tools within the 3DEXPERIENCE platform allow engineers to virtually test manufacturing scenarios, helping predict performance, identify potential bottlenecks, and optimize workflows before actual production begins. These advanced capabilities significantly reduce errors, lower costs, and accelerate time-to-market.

Digital Continuity and Traceability

By maintaining digital continuity throughout the product lifecycle, the 3DEXPERIENCE platform provides complete traceability of data from concept through production to service. Automotive manufacturers benefit from enhanced regulatory compliance, improved product quality, and greater agility in adapting to evolving market demands.

Conclusion

AI-driven smart factories embody the next evolution in automotive manufacturing, providing industry players with substantial competitive advantages. By integrating AI in automotive manufacturing and leveraging comprehensive solutions like the 3DEXPERIENCE platform, companies not only optimize current operations but also future-proof their capabilities against emerging market demands and technological advancements.

Explore how Mecanica supports automotive manufacturers in effectively implementing advanced digital manufacturing solutions to enhance engineering, production efficiency, and sustainability. Connect with our expert teams today for more info on how you can implement smart automation technologies.