Key Highlights

- DELMIA is a comprehensive digital manufacturing solution that lets you optimize production processes.

- As part of the 3DEXPERIENCE platform, it connects your virtual and real worlds of manufacturing.

- It is purpose-built for extended value network stakeholders, from suppliers to manufacturers to logistics and transportation providers.

- With DELMIA, you can achieve digital continuity, reduce costs, and improve productivity.

Introduction

Efficient manufacturing in today’s world requires smart solutions that can optimize production processes, enhance collaboration, and ensure operational excellence.

Then what is DELMIA, you ask? DELMIA is a comprehensive digital manufacturing solution that is designed to meet modern challenges and provide you with the tools you need to succeed in today’s competitive markets. With its ability to transform global production operations and drive continuous improvements across the supply chain, it is the ultimate solution for modern manufacturing needs.

As an integral part of the 3DEXPERIENCE platform, this software suite allows you to create digital models that simulate products, processes, and factory operations, providing a complete solution for business stakeholders. It offers an accessible, digital manufacturing process environment to optimize production, making collaboration easier and manufacturing more efficient at a lower cost.

So, what is DELMIA and what does that mean for you?

DELMIA is a Dassault Systèmes software suite of powerful tools and applications that enable you to define, plan, create, monitor, and control everything throughout production, including additive manufacturing processes.

It’s designed to be used on a global scale, providing manufacturers, supply chain processes, and service providers with the tools they need to collaborate, model, optimize, and perform in the ever-changing digital landscape of modern manufacturing. This software suite is specifically designed to transform global operations and help meet a growing global demand.

With its integration into the 3DEXPERIENCE platform, this set of powerful applications offers a seamless and complete solution for those looking to achieve operational excellence by connecting the virtual world of modeling and simulation with the real world of operations.

What is DELMIA vs DELMIAWorks?

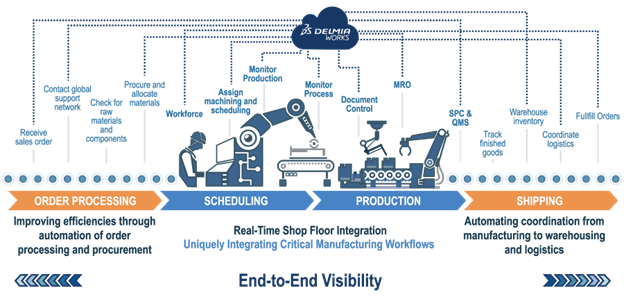

DELMIA and DELMIAWorks are two distinct software solutions offered by Dassault Systèmes, tailored to different needs within the manufacturing industry. DELMIA is a comprehensive digital manufacturing solution that integrates virtual and real-world processes, enabling users to simulate and optimize production operations on a global scale. On the other hand, DELMIAWorks (formerly IQMS) is a more focused enterprise resource planning (ERP) software designed to streamline operational processes such as inventory management, scheduling, and quality control within manufacturing facilities through enterprise solutions.

Evolution in Digital Manufacturing

The internet has transformed the way manufacturers operate, and DELMIA continues to evolve to meet these changing needs.

With Virtual twin technology you can now create a complete digital copy of your physical factories, opening the opportunity to simulate and improve production processes before implementing them in the real world. For example, the 3DEXPERIENCE role, Factory Simulation Engineer aids in designing layouts, validating them, and defining station behaviors within the platform.

This digital evolution has enhanced factory flow simulations accuracy and efficiency as well, crucial for optimizing shop floors. By simulating various scenarios, you can find bottlenecks, streamline workflows, and enhance overall performance through informed decisions.

What is DELMIA to the 3DEXPERIENCE?

Now that we have an answer to “What is DELMIA?”, let’s look at how it fits into the realm of The 3DEXPERIENCE platform.

DELMIA integrates seamlessly with other applications on the 3DEXPERIENCE platform, providing a unified environment where you can collaborate, model, optimize, and perform across the entire value network. In one, unified place you benefit from powerful toolkits like CATIA for design, SIMULIA for simulation, and ENOVIA for product lifecycle management.

By leveraging the cloud-based tools on the 3DEXPERIENCE platform, you can achieve digital continuity for better collaboration, improved decision-making, and enhanced productivity from any internet connected device, from anywhere in the world.

Advanced Process Planning and Simulation

Process engineering is a critical aspect of modern manufacturing and DELMIA provides user-friendly, accessible 3D process and resource planning tools to help you create and optimize lean manufacturing systems. Its capabilities allow you to create a virtual factory, where you can simulate and analyze different production scenarios. This lets you to identify bottlenecks, optimize workflows, and make informed decisions to improve overall production processes, making it an essential tool for industrial engineering.

With advanced process planning and simulation capabilities, you can optimize your processes, reduce costs, and improve overall operational efficiency.

Impact on Collaborative Manufacturing

DELMIA Collaborative Operations, a module within the software suite, specifically enhances team collaboration by providing a unified, real-time view for all stakeholders, promoting lean manufacturing practices, and encouraging innovation and problem-solving through better communication and 3D visualization tools. While DELMIA addresses broad operational needs, DELMIA Collaborative Operations focuses on breaking down silos and improving efficiency through collaborative efforts.

Real-Time Data Sharing and Analysis

Imagine flawless, real-time data sharing and data analysis that drive intelligent business decisions. DELMIA gives you the ability to share real-time data on demand, with any team member or stake holder, anywhere in the world for better visibility and control over production operations, leading to improved responsiveness, agility, and customer satisfaction.

By analyzing real-time data, you gain valuable insights into your production processes. Where are your bottlenecks? How can you optimize workflows? What do you need to know to make informed decisions to improve overall operational performance? Real-time data analysis allows you to proactively address these common issues, mitigate risks, and optimize production operations.

Optimizing Production

One of the key features of DELMIA is its production scheduling capabilities. You can use DELMIA to create optimized production schedules that take into account factors such as machine availability, material availability, and demand fluctuations. This ensures that production is aligned with customer demand, improving operational performance and overall customer satisfaction. Additionally, DELMIA also offers plant layout design tools, allowing manufacturers to optimize their factory layout for efficient production flow.

These lean manufacturing principles focus on eliminating waste and improving efficiency in production processes by optimizing material flow and reducing non-value-added activities to improve overall productivity and reduce costs.

These lean manufacturing principles focus on eliminating waste and improving efficiency in production processes by optimizing material flow and reducing non-value-added activities to improve overall productivity and reduce costs.

Streamlining Manufacturing Planning and Optimization

DELMIA empowers agile planning, allowing you to quickly adapt and respond to changing customer demands and market conditions. Create flexible production schedules that can be easily modified based on real-time data and customer requirements.

With optimization capabilities, you can analyze different scenarios and identify the most efficient and cost-effective production processes.

Manufacturing planning and optimization tools provide the insights and capabilities you need to make informed decisions, improve operational efficiency, and deliver products on-time and on-quality.

Efficient Resource Management

Leveraging powerful online tools you can optimize your resource usage, including raw materials, equipment, and workforce all from one unified platform. By analyzing resource availability, you can ensure that resources are allocated efficiently and effectively.

By optimizing resource management, you can reduce costs associated with overstocking or underutilization of resources. With real-time visibility into resource availability you’ll be able to make informed decisions and improve your operational efficiency.

With these resource management capabilities, manufacturers can achieve better resource utilization, reduce costs, and improve overall operational performance.

Integrating with Other Software Solutions

DELMIA offers seamless integration with other software solutions, allowing you to maximize the value of your existing systems.

Integrate with your preferred Enterprise Resource Planning (ERP) systems to synchronize your production operations with enterprise-wide business processes. Achieve better coordination, visibility, and control over your production schedules, material flow, and resource utilization.

Or, augment your Manufacturing Execution Systems (MES) to gain real-time visibility into your production operations. Monitor and control production processes, improve quality control, and easily ensure compliance with industry standards.

Naturally, DELMIA also integrates with Product Lifecycle Management (PLM) systems to help you manage product data, design changes, and engineering processes.

Enhancing Product Lifecycle Management

DELMIA enhances Product Lifecycle Management (PLM) with tools to designed to seamlessly manage product data, design changes, and engineering processes. It integrates PLM systems for a comprehensive view of your product lifecycle, facilitating effective data management, design tracking, and stakeholder collaboration. It even allows you to assess design change impacts on production, ensuring smooth implementation.

By providing real-time visibility into changes anywhere in the development or production process, this toolkit empowers you to make informed decisions and mitigate risk.

Reach out to our specialists for more info.

Frequently Asked Questions

What Makes DELMIA Different from Other Manufacturing Solutions?

DELMIA stands out from other manufacturing solutions because of its unique features and capabilities that enable manufacturers to achieve operational excellence. With its comprehensive set of tools for process planning, simulation, robotics, and production optimization, it offers a complete solution for manufacturers looking to optimize their production operations and improve overall performance. Its ability to handle complex business processes and provide advanced manufacturing operations management sets it apart from other manufacturing solutions in the market.

How Can Businesses Get Started with DELMIA?

Getting started with DELMIA involves a systematic implementation process that includes training, customer relationship management, and collaboration with service operators and transportation providers. Businesses can begin by assessing their manufacturing needs and goals, identifying the areas where this software suite can add value, and defining a roadmap for implementation.

What is DELMIA?

DELMIA is a cutting-edge software platform that revolutionizes collaborative manufacturing by enhancing team collaboration and optimizing production processes. It offers a range of tools for process planning, simulation, robotics, and production optimization. From efficient resource management to seamless integration with ERP and PLM systems, it provides a comprehensive suite of solutions to drive innovation and productivity.